News from LabRulezICPMS Library - Week 16, 2025

LabRulez: News from LabRulezICPMS Library - Week 16, 2025

Our Library never stops expanding. What are the most recent contributions to LabRulezICPMS Library in the week of 14th April 2025? Check out new documents from the field of spectroscopy/spectrometry and related techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT SPECTROSCOPY/SPECTROMETRY RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezGCMS libraries.

This week we bring you application notes by Agilent Technologies, Metrohm and Shimadzu and other document by Thermo Fisher Scientific!

1. Agilent Technologies: The Role of UV-Vis and ICP-OES Spectroscopy in Lithium-Ion Battery Recycling Methods

Supporting a one-step hydrometallurgical recycling method for leaching metals from cathode materials

- Application note

- Full PDF for download

LIBs have powered portable electronics for decades. However, the growing demand from the electric vehicle and energy storage sectors has raised concerns about managing the increasing volume of batteries reaching the end of their functional life. While the disposal of LIBs presents significant environmental challenges, it also offers opportunities for recovering valuable materials, paving the way for more sustainable practices.

LIB manufacturers rely on a steady supply of critical elements such as lithium (Li), cobalt (Co), nickel (Ni), and manganese (Mn) for use in key battery components such as the cathode. Recycling spent LIBs and recovering metals helps meet the growing demand for these resources.

Traditional methods for recycling spent LIBs rely on multistep hydrometallurgical or pyrometallurgical processes that are costly, energy-intensive, and environmentally hazardous.1,2 A more sustainable and cost-effective hydrometallurgical recycling method has been developed, which simplifies the conventional multistep approach into a single step by integrating the pretreatment and leaching stages. This method employs contact-electro-catalytic (CEC) technology, a green catalytic process that uses ultrasonic-assisted metal leaching with silicon dioxide (SiO2 ) as a recyclable catalyst.3,4 CEC processes use electron transfer during liquid-solid contact electrification to generate free radicals to catalyze chemical reactions.

Analytical techniques such as UV-Vis spectroscopy and ICP OES provide valuable data that can be used to optimize and monitor the efficiency of the CEC process. These techniques are essential for measuring radical generation, monitoring metal dissolution, evaluating process performance, and verifying the purity of any recovered materials.

The CEC recycling process

The CEC recycling process first involves the separation of the main components from spent LIBs. Metals can then be leached from cathode materials such as lithium cobalt (III) oxide (LCO) or lithium nickel manganese cobalt oxides (NCM). As outlined in Figure 1, the cathode material is mixed with organic acids such as malic acid (C4 H6 O5 ) or citric acid (C6 H8 O7 ), a SiO2 catalyst is added, and ultrasound is applied for approximately 6 hours of reaction time.3,4 UV-Vis spectroscopy an ideal technique for monitoring CEC-generated radicals and optimizing leaching conditions. The extracted metals are then processed back into LiCoO2 , NCM622, and NCM712 cathode powders using precipitation methods or sol-gel synthesis and high-temperature calcination at 850 to 900 °C, respectively. ICP OES is widely used to determine metals and other elements in LIB battery materials, including regenerated cathode active materials.5 Finally, the SiO2 catalyst can be recovered by filtration.

Experimental

UV-Vis spectroscopy analysis

An Agilent Cary 3500 Multicell Peltier UV-Vis spectrophotometer (Figure 2) with Agilent Cary UV Workstation was used to monitor metal-ion release and radical generation. Spectral analysis focused on the detection of metal ions and free radicals that facilitate metal dissolution. The following specific absorption peaks were tracked to confirm leaching: 390 nm for Ni2+, 508 nm for Co2+, and 660 nm for Mn2+. Radical scavenger tests (using p-benzoquinone, silver nitrate (AgNO3 ), and tert-butanol ((CH3 ) 3 COH)) confirmed the presence of superoxide, and electron and hydroxyl radicals, which are crucial for binder oxidation and metal reduction. UV-Vis spectroscopy provides real-time monitoring of radicals that promote leaching efficiency. Its non-destructive nature makes it ideal for continuous process control.

ICP-OES analysis

An Agilent 730 ICP-OES, which had been superseded by an Agilent 5800 Vertical Dual View (VDV) ICP-OES, was used to evaluate metal recovery efficiency. ICP-OES enables the detection of multiple elements with high sensitivity, providing precise quantification of metal concentrations. A high level of accuracy is needed to ensure that recovered materials meet industry standards. The ICP-OES instrument was calibrated using certified standards to ensure accurate quantification. The concentrations of Li, Ni, Co, and Mn in the leachates were measured to assess leaching performance and impurity levels.

Conclusion

This study highlights the critical role of UV-Vis spectroscopy and ICP-OES in optimizing and monitoring contact electro catalytic (CEC)-assisted one-step hydrometallurgical recycling processes, supporting a circular economy for lithium-ion batteries. UV-Vis provided real time tracking of metal dissolution and radical activity, while ICP-OES ensured precise quantification of metal recovery efficiency and metal impurity levels. The results confirm that eco-friendly, cost-effective CEC recycling methods can achieve high metal recoveries from spent cathode active materials (CAMs) such as LiCoO2 and NCM, ensuring material purity of regenerated CAMs.

2. Metrohm: Online analysis of copper, tin, and zinc in white bronze baths by XRF

- Application note

- Full PDF for download

Single-metal plating is a viable surface finishing solution. However, there is a limit to how much it can improve a surface’s properties. In contrast, codepositing two or more metals as an alloy coating allows for improvements tailored to specific applications [2].

White bronze is a type of tri-metal alloy, meaning it consists of three different metal elements [3]. Specifically, it is an alloy of Cu, Sn, and Zn (otherwise known as CTZ), carefully engineered to provide superior corrosion resistance and a bright, uniform finish.

The white bronze bath used in electroplating considerably improves both the chemical and physical properties of various metal products. When carefully applied to surfaces, the tri-alloy improves corrosion resistance while providing a visually appealing, silverywhite finish [1]. This procedure is commonly used in the manufacture of jewelry and decorative goods, as it increases the durability and appeal of metal products [1].

One of the primary challenges of maintaining a white bronze bath is ensuring the correct ratio of Sn, Cu, and Zn [1]. An imbalance in the concentration of these elements can lead to non-uniform deposits, which affects the aesthetic and functional properties of the plated layer.

Cyanide compounds are often present in white bronze plating baths, primarily because of their ability to form stable complexes with copper [4]. They ensure efficient metal deposition and a smooth, uniform coating. This cyanide-copper complex helps to control the plating rate and improve the overall quality of the finished layer.

Small fluctuations in metal concentrations can significantly impact the performance of the bath. This leads to issues such as dull deposits, fragile coatings, or poor adhesion. These fluctuations can arise from variations in bath replenishment, consumption rates, or contamination. This makes continuous monitoring essential for stable operation.

Traditional monitoring methods often result in process downtime due to the time required for manual sampling, chemical preparation, and analysis. The labor-intensive nature of these methods also increases the potential for human error, which in turns reduces the reliability of the data collected.

APPLICATION

White bronze bath samples were measured using a tungsten anode source XRF spectrometer. This system ensures high accuracy for Sn, Cu, and Zn detection by using characteristic X-ray excitation. Figure 2 shows the generated spectra with distinct peaks corresponding to Sn, Cu, and Zn in the electroplating bath solution.

While the 2060 XRF Process Analyzer (Figure 3) provides real-time monitoring of the metal concentrations in plating solutions, complementary techniques such as titration can also be incorporated to monitor additional critical bath parameters – like pH and cyanide levels. This combination of methodologies not only enhances process control but also provides a comprehensive solution unique in the market, allowing operators to ensure both plating quality and operator safety with a single, integrated analytical approach.

Conclusion

An XRF electroplating bath analyzer provides a fast and reliable solution for real-time monitoring of Sn, Cu, and Zn concentrations in white bronze plating baths. With its speed, ease of use, and nondestructive nature, it is an ideal tool for optimizing and controlling the plating process. Using X-ray fluorescence for this purpose helps maintain deposit quality and reduces operational costs. To further improve process efficiency, Metrohm Process Analytics offers the 2060 XRF Process Analyzer which enables automated online monitoring and provides continuous, real-time insights into bath chemistry.

3. Shimadzu: Determination of Essential and Toxic Elements in Urine by ICPMS-2050

- Application note

- Full PDF for download

User Benefits:

- Utilizing CRM Urine Control samples streamlines the workflow and minimizes the risk of errors.

- ICPMS-2050 can achieve accurate analysis with lower argon gas consumption and running cost using mini torch.

- Internal standard fluctuation can be readily observed using the Internal Standard Intensity Fluctuation Graph function of LabSolutionsTM ICPMS.

Biomonitoring is the process of measuring specific chemicals or metabolites in biological specimens, such as urine and blood serum. It is an important tool for assessing human exposure to environmental contaminants. One of the methods involves measuring the concentration of trace elements, such as arsenic, cadmium, lead and mercury.

Urine is an ideal sample for biomonitoring because the sample collection is both non-invasive and relatively simple. In addition, many trace elements are excreted predominantly in urine as their original form or metabolites1). Graphite furnace atomic absorption spectrometry (GFAAS) has been used by clinical laboratories to determine trace elements in urine. However, as GFAAS is a mono-elemental technique, the analysis could be time consuming when many samples are measured for multiple element analysis.

In recent years, Inductively Coupled Plasma Mass Spectrometry (ICP-MS) has become the preferred technique for urine analysis due to its ability to detect multiple elements simultaneously, wide dynamic linear range and high sensitivity. Furthermore, with collision/reaction cell technology equipped in ICP-MS, interference such as polyatomic interference can be eliminated. In this study, an ICP-MS method was developed to determine the concentration of nineteen toxic and essential elements in certified reference material (CRM) of urine using Shimadzu ICPMS-2050 (Fig. 1).

Conclusion

This application news highlights that the ICPMS-2050 is well suited for analyzing essential and toxic elements in urine samples. With its high sensitivity and robustness, the ICPMS2050 facilitates simultaneous analysis across a broad concentration range, from low to high. Additionally, the spike recovery results demonstrate the method's high accuracy.

4. Thermo Fisher Scientific: Finding the right technique for seamless elemental analysis in your laboratory

- Other document

- Full PDF for download

Inductively coupled plasma – optical emission spectroscopy (ICP-OES)

ICP-OES derives its analytical data from the emission spectra of elements following excitation in a high-temperature plasma. Like the emissions seen in fireworks, caused by the addition of strontium or barium, for example, to the mixture, all elements emit light of specific wavelengths upon excitation, both in the visible range of the spectrum and in the UV range.

Modern ICP-OES systems, like the Thermo Scientific™ iCAP™ PRO Series ICP-OES (Figure 1), combine fast and sensitive analysis with the well-known robustness that has made ICP-OES an established technique in environmental testing laboratories and in industrial applications. Wavelengths with different relative intensities can be utilized to calibrate across wider calibration ranges.

The sample (typically a liquid) is introduced into the plasma, and the optical system (spectrometer) is used to separate elementspecific wavelengths of light and to focus the resolved light onto the detector as efficiently as possible.

In ICP-OES, the plasma can usually be observed in two ways. Radial observation monitors a cross-section of the plasma, whereas axial observation captures the entire length of the plasma along its axis. The radial plasma view is slightly less sensitive compared to the axial view; however, it is preferable when analyzing difficult samples such as organics or very high amounts of dissolved solid matrices. Axial observation is selected for best detection limits, as the quantity of light observed is increased. However, it is more susceptible to interferences.

For the analysis of elements with emission in the UV range, for example lead (220.353 nm), arsenic (193.759 nm), or phosphorous (177.495 nm), it is imperative that optical pathways leading into the spectrometer are free from air, otherwise absorption of light could occur. The iCAP PRO Series ICP-OES spectrometer can be purged with argon or nitrogen, and analysis can be started within 5 minutes after switching on the instrument from standby (model dependent).

Inductively coupled plasma mass spectrometry (ICP-MS)

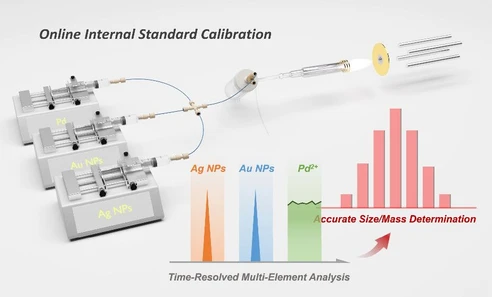

The use of mass spectrometry in conjunction with an ICP as an ion source was commercialized almost immediately after its first publication. Since then, ICP-MS is the technique of choice for the lowest detection limits and has seen a growing number of applications, including speciation analysis, targeted and spatially resolved analysis, size- and number concentration of nanoparticles, and even microplastic characterization. State-ofthe-art instruments like the Thermo Scientific™ iCAP™ MX Series ICP-MS allow sub ng∙L-1 detection limits to be achieved, while at the same time being able to cope with samples containing several thousand mg∙L-1 of matrix load.

An ICP-MS system comprises five basic parts: the sample introduction system, plasma, vacuum interface, collision/reaction cell, ion optics with mass analyzer (Figure 3).

A long-standing limitation in ICP-MS has been a restriction in the amount of total dissolved solids (TDS) that can be introduced to the system without affecting data quality. For previous generations of ICP-MS instruments, 0.2% (m/m) of solids has often been the upper limit. However, recent innovations, like the use of automatic dilution of the sample using argon gas prior to the plasma (easyAGD) in combination with intelligent control of the interface region, have enabled the extension of accessible samples.

Following ionization in the plasma, newly generated ions are transferred to the mass analyzer via a vacuum interface. This is a crucial part of ICP-MS and involves a pair of water-cooled cones with an intermediate vacuum stage between atmospheric pressure and the high vacuum of the mass spectrometer. The design and parameters applied here influence the system’s sensitivity, its ability to be unaffected by matrix effects, and, last but not least, most of the typical interferences observed in ICP-MS originate from the interface region.

Ions generated in the plasma will be separated according to their mass to charge ratio (m/z) using a mass analyzer. Quadrupole instruments are typically used in routine labs since they are relatively easy to operate and maintain.

Summary and conclusion

Both technologies share many powerful advantages for elemental analysis, but there are also differences. Figure 4 provides an overview.

For a laboratory seeking a reliable workhorse to tackle a wide range of possible sample types with detection limits in the µg∙L-1 range, ICP-OES is the perfect choice. Because of its ability to perform multi-elemental analysis, it is becoming an attractive alternative for laboratories looking at increasing the number of analytes and lowering achievable detection limits from atomic absorption. ICP-OES can be flexibly set up to analyze aqueous samples with variable amounts of total dissolved solids as well as organic solvents like fuels or lubricants. Because of its unique optical and detection system design, the iCAP PRO Series ICP-OES can allow highly sensitive analysis but also offer sample turnover times well below 60 s for high throughput testing of soils or fertilizers. ICP-MS is the right choice for laboratories seeking to futureproof their abilities in terms of detection limits. With modern ICP-MS systems, detection power can be combined with matrix robustness, so that samples that used to be predominantly run on GF-AAS and ICP-OES are within reach for ICP-MS. Recent innovations in the iCAP MX Series ICP-MS will allow laboratories to increase productivity by reducing the need for maintenance and improved overall laboratory workflows. Laboratories seeking flexibility and readiness for advanced applications, such as speciation analysis, laser ablation, or nanoparticle analysis, will find a powerful solution to fulfill their needs with the iCAP MTX ICP-MS.