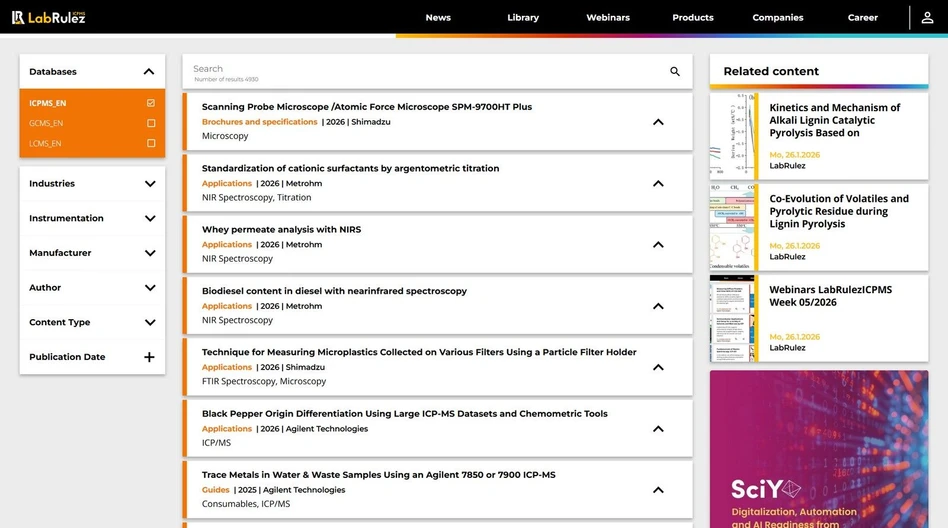

News from LabRulezICPMS Library - Week 05, 2026

LabRulez: News from LabRulezICPMS Library - Week 05, 2026

Our Library never stops expanding. What are the most recent contributions to LabRulezICPMS Library in the week of 26th January 2026? Check out new documents from the field of spectroscopy/spectrometry and related techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT SPECTROSCOPY/SPECTROMETRY RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezGCMS libraries.

This week we bring you application notes by Agilent Technologies, Metrohm and Shimadzu and brochure by Thermo Fisher Scientific!

1. Agilent Technologies: Thin Multilayer Analysis Using the Agilent 8700 LDIR Chemical Imaging System

Rapid micrometer-scale measurement of layer thickness and composition identification in laminated materials

- Application note

- Full PDF for download

Multilayer laminate materials represent a structurally and chemically complex system. They often comprise several distinct polymer layers that are engineered for specific functional roles, despite having total thicknesses of only a few hundred microns. Each layer contributes unique properties such as mechanical strength, barrier performance, or environmental protection, depending on its chemical composition and thickness. Accurate identification and measurement of these thin layers is therefore critical, as defects or deviations in layer thickness can compromise product integrity. Weaknesses can cause failures through damage, potentially resulting in safety issues for the user.

Precise mapping and micrometer-scale thickness analysis is essential during the development, quality control, and troubleshooting of multilayer materials. The Agilent 8700 Laser Direct Infrared (LDIR) chemical imaging system offers a powerful solution for this application. By combining IR spectroscopy with high-resolution imaging, the system enables chemical identification and visualization of polymer layers with exceptional spatial detail. Enhanced by the intuitive Agilent Clarity software, the 8700 LDIR delivers a fast and effective workflow for multilayer material characterization, addressing key needs in quality assurance, failure analysis, and reverse engineering.

Results and discussion

User-generated spectral library

Following sample preparation, the 8700 LDIR high‑magnification visible camera provided an overview of the laminate structure of sample 1, revealing three distinct layers. The total thickness of the sample and each layer was measured using the Clarity software ruler feature. As shown in Figure 3, the total thickness of sample 1 based on the visible image was measured to be 150 µm (layer 1: 50 µm; layer 2: 50 µm; layer 3: 50 µm). A high‑resolution IR image was then acquired at 1,442 cm–1 with a 1 µm pixel size, enabling detailed visualization of the layer morphology under infrared light (Figure 3).

Conclusion

The Agilent 8700 LDIR chemical imaging system provides a powerful, non-destructive solution for multilayer analysis across diverse applications ranging from food packaging to battery separators. By combining a laminate holder, high-magnification imaging, IR imaging, and line profile spectral collection, the method delivers clear insights into layer thickness, morphology, and material composition. The ability to quickly build custom spectral libraries within the Agilent Clarity software further enhances its utility, especially for identifying unknown materials or contaminants in multilayer materials. The 8700 LDIR multilayer analysis workflow supports both R&D innovation in advanced materials and routine quality assurance across different industries.

2. Metrohm: Almond analysis with near-infrared (NIR) spectroscopy

Multiparameter determination of moisture, fat, and protein

- Application note

- Full PDF for download

Almonds are nutritious edible nuts from the almond tree and can be eaten whole or processed in other foods. During processing, quality control (QC) parameters like moisture levels are checked to ensure that the correct percentage is reached before moving on to other stages (e.g., grinding or packaging). When determining almond quality, destructive analytical techniques are helpful but can involve extensive sample preparation and solvent extractions. These traditional techniques are also slow and expensive. Nondestructive near-infrared spectroscopy (NIRS) is a great alternative because it is fast, simple, and cost effective [1]. In this study, almond moisture content (water content), protein content, and fat have been measured using NIRS. NIR spectroscopy offers the rapid and reliable prediction of several quality parameters in seconds without any sample preparation.

EXPERIMENTAL EQUIPMENT

60 samples of ground almonds and 60 samples of whole almonds were measured on a Metrohm NIR Analyzer. All measurements were performed in reflection mode (1000–2250 nm) using the large cup accessory. The samples were measured in rotation to collect spectral data from diverse areas. Spectral averaging of signals from several spots helped to reduce sample inhomogeneity. Metrohm software was used for all data acquisition and prediction model development.

CONCLUSION

This Application Note demonstrates that almond protein content analysis, almond fat content analysis, and almond water content (or almond moisture content) analysis can be done with NIRS. NIR spectroscopy offers users a faster, simpler, highly accurate alternative to standard analytical methods for the analysis of ground and whole almonds during processing and final product quality control (Table 1). By using NIRS, all of these parameters can be measured simultaneously without sample preparation, saving time and money.

3. Shimadzu: Technique for Measuring Microplastics Collected on Various Filters Using a Particle Filter Holder

- Application note

- Full PDF for download

User Benefits

- Particle filter holders provide clear microscope images of samples, enabling highly accurate measurements.

- Microplastics can be analyzed accurately and efficiently by using a particle filter holder with a high-speed mapping program and a particle analysis program.

Since microplastics (MPs) (with diameters ranging from a few µm up to 5 mm) are widely recognized as an environmental problem in marine environments, Japan’s Ministry of the Environment has issued guidelines for preparation and measuring MPs in environmental surface waters. 1)

The guidelines include examples of using a Fourier transform infrared spectrophotometer (FTIR) to identify plastics by the total reflectance measurement method. However, to identify fine MPs, they recommend using instruments like infrared microscopes.

In recent years, an increasing number of studies have analyzed fine MPs smaller than 100 µm. Measuring MPs with an infrared microscope requires collecting samples on a filter. Various types of filters can be used for infrared microscopes, each with unique characteristics. But if a filter cannot be held horizontal during drying or measuring, it can develop wrinkles that might decrease measurement accuracy. Therefore, a particle filter (PF) holder was developed that can be placed directly on an infrared microscope stage while holding the filter horizontally. This article describes using the IRXross Fourier transform infrared spectrophotometer, an AIMsight infrared microscope (Fig. 1), and a PF holder to evaluate the properties of various filters and measure a standard sample of MPs.

Example of Measuring MPs

Polystyrene (PS), polyethylene (PE), and polypropylene (PP) particles that fell through a 100 µm mesh were dispersed in purified water. They were then collected by suction filtering through PTFE, Al2O3, Au/PC, and stainless steel filters (Table 1). After collecting the particles, the filters were dried using a PF holder. Fig. 5 shows the filter holder placed in the infrared microscope. Measurement condition settings are indicated in Table 2. The PTFE and Al2O3 filters were measured by the transmission method, whereas the stainless steel and Au/PC filters were measured by the reflection method. For the highspeed mapping program in this measurement, a peak detection range of 3,400 to 2,400 cm-1 was specified for detecting the signal from hydrocarbons (C-H). If there are peaks in that range, the range will be scanned the specified number of times. A tiled image of each filter is shown in Fig. 6. The areas marked with a yellow box were measured. For more information about the high-speed mapping program, refer to Application News No. 01-01001-EN.

Conclusion

This article describes using a PF holder to collect fine microplastic particles on various types of filters, and it provides a summary of the characteristics of each filter. Since there are differences in the wavenumber ranges and data acquisition methods for each filter type, users need to understand the individual characteristics of a filter when using it. The results also show that by using a PF holder to hold the filter flat, fine microplastic particles can be conveniently measured with an infrared microscope to obtain clear images and accurate measurements. Furthermore, a highspeed mapping program and particle analysis program can be used to accurately and efficiently analyze microplastics.

4. Thermo Fisher Scientific: Raman at the speed you need - Thermo Scientific DXR3 Raman Family

- Brochure

- Full PDF for download

The Thermo Scientific DXR3 Raman Family is a versatile portfolio of Raman spectroscopy instruments designed to deliver high-quality chemical information quickly and reliably across a wide range of applications. Built on a shared, modular platform, the family includes the DXR3 Raman Microscope, DXR3xi Raman Imaging Microscope, and DXR3 SmartRaman Spectrometer, enabling users to choose the optimal configuration for point analysis, high-resolution imaging, or bulk sample characterization. All systems emphasize ease of use, reproducibility, and rapid data acquisition, making advanced Raman analysis accessible to both expert spectroscopists and routine laboratory users.

The DXR3 Raman Microscope provides research-grade performance with sub-micrometer spatial resolution and intuitive point-and-shoot operation, supporting demanding analytical tasks such as microanalysis, depth profiling, and chemical mapping. For applications requiring fast, high-resolution chemical imaging, the DXR3xi Raman Imaging Microscope delivers exceptional stability, automated feature identification, and rapid image acquisition over both small and large areas. Its advanced EMCCD detector technology and intelligent autofocus significantly reduce experiment time while maintaining high data quality, making it ideal for materials research, pharmaceuticals, and life sciences.

The DXR3 SmartRaman Spectrometer is optimized for high-performance bulk sample analysis in busy analytical laboratories. Featuring a large sampling compartment and flexible accessories, it accommodates a wide range of sample formats—from powders and tablets to liquids in bottles or vials. Variable Dynamic Point Sampling (VDPS) technology enables representative averaging over large sample areas, improving reproducibility and reducing sampling bias. Together with multiple excitation laser options and interchangeable gratings, the system supports diverse analytical workflows with minimal maintenance.

Across the entire DXR3 family, pre-aligned, user-exchangeable Smart Components, automated alignment and calibration, and powerful OMNIC™ software ensure consistent performance and simplified operation. Extensive microscopy, macro-sampling, and automation options allow systems to be tailored to specific applications, while robust system qualification and diagnostics support long-term reliability. Overall, the DXR3 Raman Family combines speed, flexibility, and analytical confidence, making it a comprehensive solution for modern Raman spectroscopy in research, quality control, and industrial environments.