News from LabRulezICPMS Library - Week 45, 2025

LabRulez: News from LabRulezICPMS Library - Week 45, 2025

Our Library never stops expanding. What are the most recent contributions to LabRulezICPMS Library in the week of 3rd November 2025? Check out new documents from the field of spectroscopy/spectrometry and related techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT SPECTROSCOPY/SPECTROMETRY RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezGCMS libraries.

This week we bring you application notes by LECO and Shimadzu and poster by Thermo Fisher Scientific!

1. LECO: Determination of Carbon, Hydrogen, and Nitrogen in Biomass

- Application note

- Full PDF for download

Carbon, Hydrogen, and Nitrogen determination is part of the ultimate analysis of solid biofuel materials. Determining the content of these elements can help to characterize the materials and provide information that can be utilized in calculating material/energy balances. In addition, this information may be used to calculate efficiencies, as well as emissions potentials, for solid biofuel materials.

Instrument Model and Configuration

The LECO CHN828 is a combustion Carbon, Hydrogen, and Nitrogen determinator that utilizes a pure Oxygen environment in a vertical quartz furnace, ensuring complete combustion and superior analyte recovery. Combustion gases are swept from the furnace through an afterburner containing a reagent to scrub Sulfur compounds from the gas stream prior to collection in the ballast volume. The combustion gases are collected in a ballast where they equilibrate and mix before a representative aliquot (3 cm3 or 10 cm3 volume) of the gas is extracted and introduced into a flowing stream of inert gas (Helium or Argon) for analysis. The aliquot gas is carried to an infrared cell (IR) for the detection of Carbon (CO2) and a thermal conductivity cell (TC) for the detection of Nitrogen (N2). A separate portion of the ballast gas is transferred to an IR cell for the detection of Hydrogen (H2O).

Thermal conductivity detectors work by detecting changes in the thermal conductivity of the analyte gas compared to a reference/carrier gas. The greater the difference between the thermal conductivity of the carrier gas and the analyte gas, the greater the sensitivity of the detector. The CHN828 supports either the use of Helium or Argon as the instrument's carrier gas. When used as a carrier gas, Helium provides the highest sensitivity, and the best performance at the lower limit of the Nitrogen range. Argon can also be used as a carrier gas. However, the thermal conductivity difference between Argon and Nitrogen is not as great as the thermal conductivity difference between Helium and Nitrogen, therefore the detector is inherently less sensitive when using Argon as a carrier gas.

TYPICAL RESULTS

Data was generated utilizing a linear, full regression calibration for Carbon determination, and linear, force through origin calibrations for Hydrogen and Nitrogen determination, using fractional masses (~0.07 g to ~0.15 g) of 502-642 (Lot 1019) LCRM Phenylalanine (65.47% C, 6.74% H, 8.46% N). The calibration was verified using LECO 502-896 (Lot 1003) LCRM EDTA (41.08% C, 5.52% H, 9.58% N). An atmospheric blank was determined using ground sucrose and was utilized to compensate for entrapped atmosphere. A moisture value for the samples was obtained utilizing a LECO TGM800 on the day of analysis and entered into the software to correct for moisture. Results are reported on a dry basis.

2. Shimadzu: Ultrasonic Fatigue Test for Hourglass-shaped Metal Test Specimens with Parallel Sections

- Application note

- Full PDF for download

User Benefits

- The ultrasonic fatigue tester is capable of testing at a repetition rate of 20 kHz and can complete tests with 109 cycles (1 billion cycles) in only about 14 hours.

- It is possible to test hourglass-shaped test specimens with parallel sections specified in the Chinese National Standard GB/T 43896 “Metallic materials-Very high cycle fatigue-Ultrasonic fatigue test method.”

Fatigue is a fracture phenomenon caused by repeated loads, even within the elastic region. It is said that about 70 % of structural fracture phenomena are caused by metal fatigue. For most structural steels, there is a fatigue limit where fatigue failure does not occur even after repeated loading if the stress is less than a certain value, and the number of cycles is about 106 to 107. However, in high-strength steels such as chromium molybdenum steel, it is known that fatigue failure occurs in the ultra-high cycle range of 108 to 109 cycles, exceeding 107 cycles, due to inclusions in the material. Therefore, the standard of 107 repetitions as the maximum number of repetitions used in general fatigue tests is not sufficient, and fatigue tests with more than 109 cycles are required. On the other hand, a fatigue test with more than 109 cycles would take more than 3 years at a 10 Hz load. The ultrasonic fatigue tester used in this study is capable of testing at 20 kHz and can complete tests with 109 cycles in about 14 hours, making it ideal for measuring ultra-high cycle fatigue.

In previous reports1,2), we conducted tests on standard hourglass specimens. In November 2024, the National Standard GB/T 43896 of the People's Republic of China (Metallic materials- Very high cycle fatigue-Ultrasonic fatigue test method) was issued, so Shimadzu has added a new dimension calculation function for hourglass-shaped specimens with parallel sections to its USF2000A dedicated software, Super Sonic. In this paper, we introduce an example of measurement of an hourglass-shaped specimen with a parallel section in compliance with GB/T 43896 using SNCM439, a type ofstructuralsteel.

Instruments

The USF-2000A was used in this test. Table 1 shows the testing equipment and Fig. 1 shows the test setup. In the ultrasonic fatigue test, a longitudinal wave vibration generated by a piezo actuator causes the specimen to resonate, and stresses are applied to the specimen. The cyclic stress is not measured using a load cell, but is calculated based on the displacement of specimen's end face. In this test, an eddy current displacement meter was used to measure the displacement of the end face.

In the ultrasonic fatigue test, internal heat generation occurs due to the high repetition rate. According to GB/T 43896, the surface temperature of the high-stress part of specimen is measured, and the specimen temperature during the test is required to be within room temperature +10 °C. In order to suppress the temperature rise of the specimen, an air cooler was employed to blow cooling air onto the heated region, and intermittent operation was performed as described below.

Conclusion

In these tests, ultrasonic fatigue tests were conducted on SNCM439 hourglass-shaped specimens with a parallel section in accordance with the Chinese National Standard GB/T 43896, “Metallic materials-Very high cycle fatigue-Ultrasonic fatigue test method,” and S-N diagrams were obtained.

3. Thermo Fisher Scientific: Benefits of coupling a high-speed laser ablation system to Quadrupole Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

- Poster

- Full PDF for download

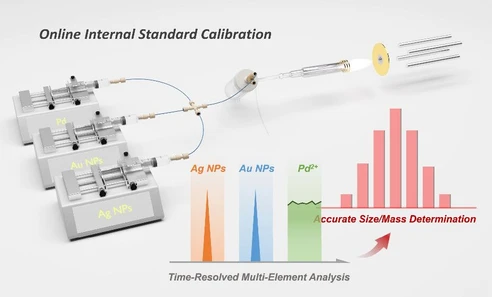

Laser Ablation (LA) coupled with ICP-MS is a well-established way to directly analyze solid samples. The main advantages of laser ablation include the ability to avoid lengthy and potentially contamination prone sample preparation protocols and the ability to obtain information about the spatial resolution of an analyte in a sample.

The interest in so-called mapping techniques has increased in recent years, calling for laser ablation systems to develop methods to improve sample transfer and therefore speed of mapping experiments. New laser-ablation systems dedicated to high-speed mapping are commercially available and can be easily coupled to quadrupole ICP-MS for such applications.

With the improvement in sample transfer and washout times from laser ablation systems, the time available to analyze discrete packets of sample from a laser pulse is drastically reduced. The limit for lateral resolution using a sequential ICP-MS, such as a quadrupole ICP-MS, is dependent on the dwell times chosen for each measured m/z channel. This has a direct impact on the signal-tobackground ratio achievable for each m/z channel; therefore, a direct impact on the final image contrast for each mapped m/z channel.

MATERIALS AND METHODS

Instrumentation

A Teledyne Photon Machines Iridia Laser Ablation System fitted with a Cobalt lowdispersion ablation chamber was directly coupled with a Thermo Scientific™ iCAP™ TQ ICP-MS. Data was acquired using Thermo Scientific™ Qtegra™ Intelligent Scientific Data Solution™ (ISDS) Software and processed using Teledyne Photon Machines HDIP Mass Spectrometry Data Analysis Software.

CONCLUSIONS

Through careful optimization of laser ablation and ICP-MS parameters, it is possible to generate high quality multi-elemental images at a fast rate. The use of new low-dispersion laser ablation cells and aerosol transfer technology is not limited to simultaneous mass spectrometers and is also applicable to sequential scanning mass spectrometers such as Quadrupole ICP-MS.

The major limitation of coupling low-dispersion Laser Ablation systems to sequential mass spectrometers is the limited number of elements that can be scanned; however, this is offset by the sensitivity and the specificity of, especially, triple quadrupole ICP-MS systems for the reduction of interferences on select analytes.

Most imaging experiments can be reduced to three or four analytes of interest, and in these cases LA-ICP-MS coupled to Triple Quadrupole ICP-MS using a low-dispersion, fast imaging setup can provide the analytical data quality required to answer challenging research questions.