Improved sampling strategy for high-performance materials: The introduction of the stethoscope cell for online-LASIL experiments

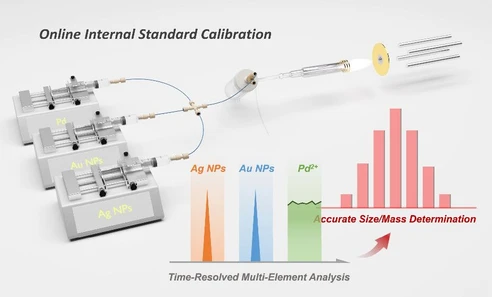

Microchemical Journal, Volume 210, 2025, 112956: Graphical abstract

Precise analysis of high-performance materials is essential for sustainable technologies. Online-LASIL combined with ICP-MS enables simple elemental quantification using liquid standards, avoiding complex digestion. To address limitations with sample geometry, a novel "stethoscope cell" was developed.

The stethoscope cell supports analysis of samples from 7–20 mm in size and up to 10 mm thick. It enables reproducible bulk and depth-resolved measurements, as demonstrated in TiW-sputter targets and protective coatings. Results showed good agreement with ICP-OES references, validating the new design for quantitative online-LASIL applications.

The original article

Improved sampling strategy for high-performance materials: The introduction of the stethoscope cell for online-LASIL experiments

Maximilian Podsednik, Maximilian Weiss, Johannes Frank, Erwin Peck, Silvia Larisegger, Helmut Riedl, Paul H. Mayrhofer, Andreas Limbeck

Microchemical Journal, Volume 210, 2025, 112956

https://doi.org/10.1016/j.microc.2025.112956

licensed under CC-BY 4.0

Selected sections from the article follow. Formats and hyperlinks were adapted from the original.

The increasing CO2 emission of the world’s population is posing one of the major challenges of the 21st century. The effects of climate change are noticeable around the globe, with a rising occurrence of extreme weather conditions [1]. To overcome this challenge, it is mandatory to develop more efficient technologies and expand renewable energy sources, resulting in a demand for new materials with improved properties [2]. For that reason, material development and design play a vital role in overcoming the challenges of the 21st century. For the optimization of novel materials and to locate errors in the production processes, a precise chemical analysis of the sample composition is essential. Besides sample stoichiometry, obtaining quantitative information about additives or unwanted contaminants is also necessary for suitable process control.

A conventional solution for that challenge would be the digestion of the sample and subsequent liquid analysis of the resulting sample solution using, e.g., inductively coupled plasma–mass spectrometry [3], or optical emission spectroscopy [4] (ICP-MS or ICP-OES), atomic absorption spectroscopy [5] (AAS). However, many novel high-performing materials, like protective [6], [7], or thermal barrier coatings [8], [9], are hard-to-digest materials, thus requiring, besides harsh conditions, corrosive or potentially harmful chemicals like HF or sample fusion. Moreover, considering thin protective coatings, the digestion of the whole system is often not advisable since the comparatively high mass of the substrate could lead to interferences in the analysis or unwanted contaminations, and selective dissolution of the coating is often not feasible.

To overcome the problems associated with sample digestion, the analysis of the solid material is recommended. Frequently applied solid sampling techniques include methods such as laser ablation inductively plasma mass spectrometry [10], [11] (LA-ICP-MS), laser-induced breakdown spectroscopy [12], [13] (LIBS), secondary ion mass spectrometry [14], [15] (SIMS), glow discharge-mass spectrometry [16] or optical emission spectroscopy [17] (GD-MS or GD-OES), or X-ray fluorescence spectroscopy (XRF). These methods allow simple analysis of chemically inert materials and enable spatially resolved analysis to differentiate between coating and substrate. However, for an accurate quantitative analysis, the mentioned methods require matrix-matched standards or certified reference materials, often unavailable for novel high-performance materials [18].

Another approach that recently demonstrated its effectiveness in spatially resolved analysis of solid materials is online-laser ablation of solids in liquids (LASIL) [19], [20], [21]. In online-LASIL, the sample is ablated into a continuously flowing carrier solution using a laser system. The liquid flow over the sample is achieved by an in-house built online-LASIL cell. As demonstrated by Muravitskaya et al. [22], the nanoparticles generated by the laser ablation of the sample behave like dissolved ions when introduced into an ICP-MS. For this reason, online-LASIL does not depend on certified reference materials or matrix-matched standards and can use commercially available liquid standards for quantification. This enables the economical and quick adaptation of online-LASIL experiments for novel, hard-to-digest materials. Looking at the online-LASIL cell design introduced by Bonta et al. [19], it becomes evident that the cavity used for the sample was optimized for sample geometries of 5 × 5 mm2 and a height of 0.5 mm. This setup also allows the analysis of smaller samples, even though the analytical performance might be reduced due to changed flow dynamics, especially for very thin samples. However, bigger samples must be fragmented to fit the size of the LASIL cell, adding additional sample preparation and increasing the risk of contamination.

This limitation of the online-LASIL cell design is addressed in this work. To conduct online-LASIL experiments without being restricted by the sample's geometry, the stethoscope cell is introduced. As the name already implies, the stethoscope cell is placed on top of the sample, enabling the analysis of samples at least 7 mm in length, and the sample thickness is mainly limited by the length of the screws used to seal the cell. To demonstrate the capabilities of the new cell design, the composition of an industrial TiW sputter target with a diameter of 450 mm was evaluated. Additionally, the applicability of the stethoscope cell is demonstrated by the analysis of boride coatings deposited on steel substrates. Those protective coatings, with their high hardness and self-lubricating properties [7], [23], are responsible for increasing the efficiency of components essential for industrial manufacturing [24].

2. Experimental

2.2. Online-LASIL measurement setup

The samples were ablated using a commercially available LIBS system, the J200 Tandem LA/LIBS (Applied Spectra Inc., Fermont, CA), with a 266 nm wavelength and a pulse width of four ns. For the analysis, the online-LASIL cell is placed in the sample stage of the system, offering the recording of spatially resolved information [25], [26]. Therefore, the cell can be universally used in laser systems from different manufacturers. The only limiting factor is the geometry of the ablation chamber, which needs to be large enough to fit the cell and the connected tubing. To maximize the setup's washout behavior, a controlled segmentation of the carrier was employed, using a six-port-valve controlled by an Arduino controller [27]. The segmentation of the carrier solution was achieved by releasing Ar-gas every 10 s for 0.3 s with a pressure of approximately 0.8 bar.

An iCAP TQ ICP-MS from (Thermo Fisher Scientific, Germany) was used as a detection system in kinetic energy discrimination (KED) mode using He as KED-gas. The nanoparticle suspension generated in the LASIL process was introduced into the ICP-MS using a PFA nebulizer and a cyclonic spray chamber. The overall flow rate of the sample introduction was 1.6 ml/min, consisting of 1.1 ml/min of the carrier solution, spiked with 1 ng/g In as an internal standard and 0.5 ml/min of the make-up solution. For the analysis of the TiW-sputter target, an HF-resistant sample introduction kit consisting of a PFA cyclonic spray chamber and a sapphire torch was used since diluted HF was used as a make-up solution. Before all experiments, the ICP-MS was tuned for the maximum intensity of the 115In signal and a CeO+/Ce+ ratio below 2 % using a solution from the manufacturer. Finally, the instrument software Qtegra Version 2.10 recorded and analyzed the data. The detailed laser and ICP-MS parameters are listed in Table 1.

2.3. Reference ICP-OES measurements

Liquid ICP-OES measurements were conducted to obtain reference values for both online-LASIL experiments. The approximately 0.2 g TiW-sputter target fragments were used for the analysis. Three samples were digested by a mixture of 1 ml HNO3 and 1 ml HF for 10 min at room temperature. For the reference measurements of the protective coatings, the coatings of interest were deposited on sapphire substrates, unaffected by the digestion parameters. The samples were broken into pieces with dimensions of approximately 5x5 mm2. For the digestion of the coatings, a mixture of 0.25 ml HNO3 and 0.25 ml HF for 30 min at 100 °C was used. After the samples cooled to room temperature, they were diluted to 40 ml and spiked with 1 µg/g Eu as the internal standard. Due to the higher sample intake of the TiW-sputter target, a second dilution by a factor of 100 was needed.

For the analysis, a Thermo iCAP 6500 ICP-OES (ThermoFisher Scientific, Germany), equipped with an HF-resistant sample introduction kit, was used as a detection system. The sample introduction was accomplished using an ASX-520 autosampler (CETAC Technologies, USA), a PTFE concentric nebulizer, a PTFE cyclonic spray chamber, and a ceramic injector tube. The detailed ICP-OES parameters can be seen in Table S2). The obtained emission signals were quantified with an external calibration using liquid ICP standards. Two emission lines per element were monitored for quantification, and the instrument software Qtegra (Version 2.8) was used to evaluate the data.

3. Results and discussion

3.1. Analytical performance of the stethoscope cell

As mentioned in the introduction, the old cell design did not only limit the analyzable samples' width and length but also their height, as the cell was optimized for standardized substrates with a thickness of 0.5 mm. Therefore, thicker samples could not be analyzed without time-consuming thinning to fulfill this precondition, and thinner samples had to be fixated to prevent the sample from moving during the analysis. The new cell design avoids all those disadvantages by using it like a stethoscope, making it easily adaptable to varying sample geometries (size and thickness).

The assembled stethoscope cell is illustrated in Fig. 2; it consists of three components machined out of polyether ether ketone (PEEK): the top part, the bottom part, and the actual stethoscope cell. The top and bottom parts are primarily needed to achieve a sealed flow of the carrier solution over the sample. To apply pressure, four bolts are screwed into the threads of the bottom part. Within the stethoscope cell, seven holes are drilled, with the outer four serving as guides to position the cell on the sample. The two drillings in the middle are equipped with PTFE tubes (outer diameter: 1.6 mm), enabling the introduction of the carrier solution. A quartz glass is placed in the cavity in the middle of the cell, allowing the ablation of the sample through a 1.5 × 4 mm2 window. Two PDMS films with channels are used to avoid leakages between the sample, the cell, and the quartz glass. Besides the sealing of the cell, the PDMS foil between the sample and the stethoscope cell enables the flow of the carrier solution over the sample. Comparable to the old design, the continuous flow of the carrier solution was achieved using a peristaltic pump (Perimax 12, SPETEC, Germany).

Microchemical Journal, Volume 210, 2025, 112956: Fig. 2. Detailed depiction of the stethoscope cell assembly, including a cross-section and the models of the “top part,” the “stethoscope cell,” and the two PDMS foils with 5 and 15 mm diameters.

Microchemical Journal, Volume 210, 2025, 112956: Fig. 2. Detailed depiction of the stethoscope cell assembly, including a cross-section and the models of the “top part,” the “stethoscope cell,” and the two PDMS foils with 5 and 15 mm diameters.

While this new design offers more flexibility regarding the sample’s geometry, there are still limitations remaining, like at least one flat surface for the analysis, a minimum sample size of 7 mm, and a maximal sample width, which is limited by the length of the four screws used for sealing the cell. The minimum size request is crucial to realize a sealed flow of the carrier solution over the sample, given by the distance of the inlet and outlet of the carrier solution. Moreover, due to the redesign, there is a slightly larger dead volume between the sample and the silica glass (cf. Fig. 2), which is necessary to ensure the stability of the stethoscope cell. Because of this increased volume, a higher flow of the carrier solution (1.6 ml/min) is necessary to ensure a sufficiently fast sample washout. While this leads to decreased analysis times, it also results in a higher dilution of the ablated material and, thus, overall, a slightly reduced sensitivity. Nonetheless, the flexibility gained to quickly adapt the measurements setup for varying sample geometries, especially their thickness, outweighs those limitations for the following applications.

3.2. Quantitative bulk analysis of an industrial sputter target

To demonstrate the quick adaptation of the stethoscope cell to different materials and applications, a roughly 10x10x2 mm3 piece of an industrial TiW-sputter target, prepared as explained in chapter 2.1, was analyzed. The analysis of the sputter target composition is ideally suited to demonstrate the advantages of the stethoscope cell. In contrast, with the old cell design, the sample would have needed to be machined to fit precisely into the 5 × 5 × 0.5 mm3 cavity. This would add time for sample preparation and increase the risk of contamination. At this point, it is worth mentioning that even for the conventional liquid ICP-OES analysis, additional time was needed since the preparation of a smaller piece was necessary to avoid large amounts of concentrated acids for complete sample dissolution since HF is required to digest the TiW-sputter target.

For this online-LASIL experiment, a 0.6 mol/l NaF buffer solution with a pH of 6, acidified with concentrated HF, was used as a carrier solution. The buffer was chosen since, according to the literature [28], HF is required to stabilize W in an aqueous solution. However, adding HF to the carrier solution was not feasible as even diluted HF slightly etched the sputter target, resulting in elevated and unstable background signals. After sample ablation, a make-up solution, consisting of a mixture of 5 % (v/v) HNO3 and 1 % (v/v) HF, was introduced via a T-piece connected with a 30 mm PTFE-tubing to the outlet of the cell, enabling transport of the ablated material to the ICP-MS without significant losses.

The transient signal of the ablated TiW-sample can be seen in Fig. 3. Besides the ablation events of six laser lines, small, reoccurring peaks can also be seen, resulting from the Ar-bubbles introduced to segment the carrier solution. For the data analysis, the signal caused by the Ar-bubbles was not considered. In this experiment, every 10 s an Ar-bubble was introduced into the carrier solution. Looking at the washout time of the ablation events, it becomes evident that the material generated in the ablation process is completely washed out within one liquid segment. This demonstrated that the combination of the new cell design and the controlled segmentation of the carrier solutions results in washout behaviors comparable to those of the old design, even when using the T-piece. As stated by Podsednik et al. [27], the washout time is mainly limited by the synchronization of the laser pattern with the liquid segments.

Microchemical Journal, Volume 210, 2025, 112956: Fig. 3. Washout behavior of the ablated TiW-sputter target using the stethoscope cell and a controlled segmentation of the carrier solution. One can see six ablation events resulting from line scans and small peaks, which reoccur every 10 s due to the introduced Ar-gas bubbles.

Microchemical Journal, Volume 210, 2025, 112956: Fig. 3. Washout behavior of the ablated TiW-sputter target using the stethoscope cell and a controlled segmentation of the carrier solution. One can see six ablation events resulting from line scans and small peaks, which reoccur every 10 s due to the introduced Ar-gas bubbles.

4. Conclusion

In recent years, online-LASIL has been successfully used to analyze various materials. However, restrictions in the required sample geometry prevented a more general application. To establish online-LASIL for a broader sample selection, this work developed a new online-LASIL cell design, which is used comparable to a stethoscope. The redesign enables the analysis of samples at least 7 mm in length, and the thickness of the samples is only limited by the length of the screws used to seal the cell. Therefore, the stethoscope cell easily adapts to varying sample geometries, guarantees a perfect fit, and minimizes sample preparation. Consequently, the stethoscope cell represents a start toward enabling geometry-independent sampling in online-LASIL experiments.

The applicability of the stethoscope cell has been shown for the analysis of a TiW-sputter target and protective coatings. Both measurements reflect the advantages of the new design by comparing the differing geometries of the TiW-sputter target (10 × 10 × 1 mm3) and the protective coatings (20 × 7 × 1 mm3). Neither sample would have been analyzable without additional sample preparation using the old cell design. While the analysis of the TiW-sputter target provides a quantitative assessment of the bulk composition, the measurements of the protective coating illustrate a depth-resolved application, enabling a clear differentiation between the substrate and applied coating.

The current operation of the stethoscope cell requires increased flow speed to flush the volume over the sample, which results in an overall reduction in sensitivity. However, this issue is of minor importance in the shown application examples because only the main components were examined. Further improvements will be focused on reducing the cells’ dead volume to enable fast washouts with reduced flow rates.