A new material can eliminate bacteria and viruses —all it needs is light

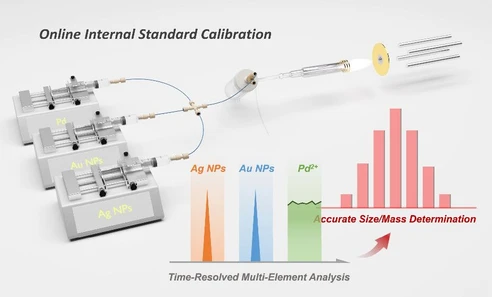

EcoMat. 7. 10.1002/eom2.70009: Figure 1 Schematic representation of individual steps towards the synthesis of NGA PVA-DBA coating and its use for light-induced antiviral/antibacterial treatment. After synthesis, NGA was embedded into the PVA-DBA matrix. The coating showed high antimicrobial activity against viruses and bacteria using 5 to 10 min of NIR irradiation.

Killing bacteria using light. That’s how simple surface disinfection could become in the future. That’s why scientists from EMPA (Swiss Federal Laboratories for Materials Science and Technology), CATRIN at Palacký University, and the Centre for Energy and Environmental Technologies (CEET) at VSB–TUO have begun developing a special coating whose antimicrobial effect can be activated by infrared light. This material is also gentle on the skin and environmentally friendly – and it could become a new weapon in the fight against antibiotic-resistant bacteria. Its first practical use is currently being prepared in the field of dentistry. The results were published in the journal EcoMat.

A novel material that is eco-friendly, biocompatible, and metal-free is designed to rapidly and locally eliminate microorganisms. It is based on polyvinyl alcohol—a biocompatible plastic commonly used, for example, in the food industry. “A specially synthesized, nitrogen-enriched graphene acid has been incorporated into this matrix. Thanks to its chemical properties, it has significant antimicrobial potential. Its full effect is unleashed when exposed to near-infrared light. The material then employs a dual strategy: it converts light energy into heat, which kills bacteria, and at the same time generates oxygen radicals that disrupt the membranes of pathogens,” explained Radek Zbořil from CATRIN and CEET.

EcoMat. 7. 10.1002/eom2.70009: Figure 1 Schematic representation of individual steps towards the synthesis of NGA PVA-DBA coating and its use for light-induced antiviral/antibacterial treatment. After synthesis, NGA was embedded into the PVA-DBA matrix. The coating showed high antimicrobial activity against viruses and bacteria using 5 to 10 min of NIR irradiation.

EcoMat. 7. 10.1002/eom2.70009: Figure 1 Schematic representation of individual steps towards the synthesis of NGA PVA-DBA coating and its use for light-induced antiviral/antibacterial treatment. After synthesis, NGA was embedded into the PVA-DBA matrix. The coating showed high antimicrobial activity against viruses and bacteria using 5 to 10 min of NIR irradiation.

The advantage of this approach is that it works entirely differently from conventional antibiotics. The material thus protects against a wide spectrum of microorganisms without contributing to the development of resistance. “Our laboratory tests clearly confirmed the material’s effectiveness against both bacteria and viruses. Surfaces that frequently come into contact with infectious agents—such as door handles in hospitals or furnishing in operating theatres—are particularly well-suited for this innovation,” said Giacomo Reina from EMPA.

The first practical use of the new coating is being developed for dental medicine. EMPA is collaborating with the Center for Dental Medicine at the University of Zurich to develop a dental splint with firmly embedded graphene acid. Since near-infrared light penetrates several centimetres into tissue, the splint can be placed in the mouth, repeatedly activated by an external light source, and used to destroy microorganisms inside the oral cavity. Oral microflora is an especially tough opponent—complex bacterial communities hide in hard-to-reach niches, protected by layers of their own mucus. Antibiotics and conventional disinfectants struggle to penetrate these biofilms. This allows bacteria to damage teeth or even cause serious infections elsewhere in the body.

Antibiotic-resistant bacteria and emerging viruses pose an increasingly serious threat to the global healthcare system. They are associated with approximately 5 million deaths annually, with the COVID-19 pandemic alone accounting for over 20 million fatalities. Scientists are therefore seeking new strategies to combat these pathogens. One of their goals is to prevent the spread of resistant bacteria and viruses through smart materials and technologies.

The original article

Light Irradiation of N-Doped Graphene Acid: Metal-Free Strategy Toward Antibacterial and Antiviral Coatings With Dual Modes of Action

Giacomo Reina, David Panáček, Krista Rathammer, Stefanie Altenried, Philipp Meier, Paula Navascués, Zdeněk Baďura, Paula Bürgisser, Vera Kissling, Qun Ren, Radek Zbořil, Peter Wick

EcoMat. 7. 10.1002/eom2.70009.

https://doi.org/10.1002/eom2.70009

licensed under CC-BY 4.0

Selected sections from the article follow. Formats and hyperlinks were adapted from the original.

4 Experimental Section/Methods

4.2 NIR Irradiation

Hydrosun w575 with a wIRA filter was used as a NIR irradiation source. Irradiation experiments were conducted with a working distance of 37 cm, ensuring the following irradiance composition: Vis (590–780 nm) 46.04 mW/cm−2 (26.59%), NIR (780–1400 nm) 126.53 mW/cm−2 (73.09%), IR (> 1400 nm) 0.55 mW/cm−2 (0.32%) [98].

4.5 Characterization of NGA and NGA/PVA-DBA Coating

A profilometer (Dektak XT, Bruker) with a 12.5 μm stylus radius was used to determine the thickness and estimate the roughness of the coatings. Coating density was determined by measuring the weight of coverslips with a known surface area before and after coating using a microbalance. Raman measurements were performed using an alpha300R WITec confocal Raman spectrometer with a 532 nm laser excitation source, 5 mW, and 0.5 acquisition time, 600 g/mm. Spectra have been recorded with a 50× magnification, mapping a surface 50 × 50 μm with an xy resolution of 1 μm. After recording, spectra have been processed with WITec Control 6.1 using baseline subtraction and multicomponent analysis. The contact angle was measured in static mode by depositing distilled water drops (2 μL) with a Krüss (DSA25) device. FTIR spectra were recorded on an iS5 FTIR spectrometer (Thermo Nicolet) using the Smart Orbit ZnSe ATR accessory. Briefly, a droplet of water dispersion of the relevant material was placed on the ZnSe crystal and dried. The spectra were then acquired by summing 52 scans using a nitrogen gas flow through the ATR accessory. ATR and baseline correction were applied to the collected spectra.

The NGA sample was characterized by transmission electron microscopy (TEM) using a JEOL 2100 TEM instrument (JEOL) with an accelerating voltage of 200 kV. High-resolution transmission electron microscopy (HR-TEM) was performed with a HR-TEM TITAN 60–300 microscope with an X-FEG type emission gun, operating at 300 kV. The coating morphology was examined through scanning electron microscopy (SEM) JEOL 7900F microscope (JEOL, Japan), with an accelerating voltage of 5 kV. Fourier transformed infra-red (FTIR) spectra were obtained with an iS5 FTIR spectrometer by Thermo Nicolet, which included a Smart Orbit ATR accessory featuring a ZnSe crystal. For this, 20 μL of the sample dispersed in distilled water was applied to the ZnSe crystal and allowed to air-dry. X-ray photoelectron spectroscopy (XPS) measurements were performed using a Nexsa G2 spectrometer from Thermo Fisher Scientific, equipped with an Al Kα radiation source. The resulting data were analyzed with Avantage software. Raman spectroscopic data were acquired using a DXR Raman microscope. This process involved employing a 780 nm excitation line from a diode laser. EPR spectra were collected on an x-band (∼9.14–9.17 GHz) spectrometer, JEOL JES-X-320, equipped with a variable He temperature set-up ES-CT470 apparatus. The experimental temperature was set to 78 K. The quality factor (Q) was kept above 650. High purity quartz tubes (Suprasil, Wilmad, ≤ 0.5 OD) and the accuracy of the g-values was determined by comparison with a Mn2+/MgO standard (JEOL standard). The microwave power was set to 1.0 mW to avoid any power saturation effects. A modulation width of 0.35 mT and a modulation frequency of 100 kHz were used. EPR spectra were collected with a time constant of 30 ms and a sweep time of 2 min with two accumulations to improve the signal-to-noise ratio.