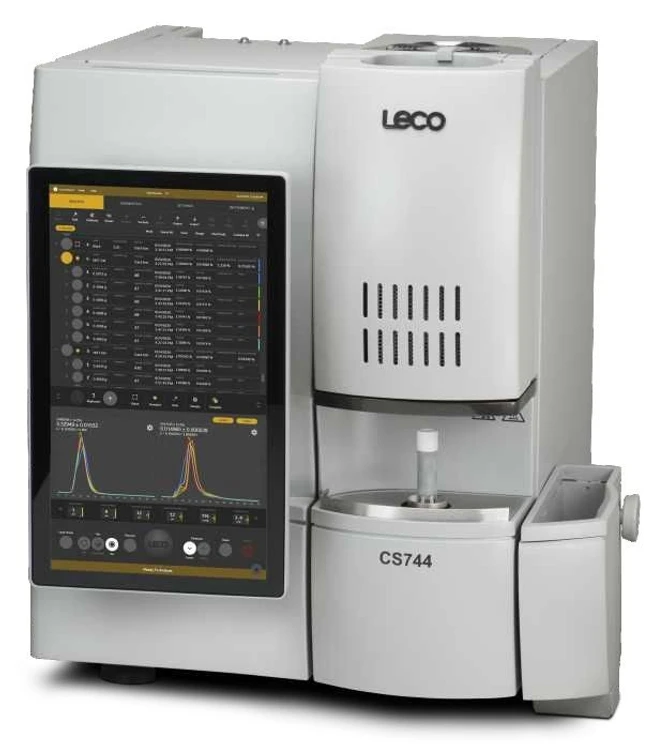

LECO 744 Series Combustion Analysis for Carbon and Sulfur

Redefine how carbon and sulfur are determined in metals, ores, and other inorganic materials with the LECO 744 Series. Developed using extensive customer feedback and innovative engineering, the 744 Series combines a high-performance induction furnace with LECO’s immersive Cornerstone® touch-screen software platform. Advanced hardware features, including an improved IR cell design and optional automation, work together to improve usability, increase laboratory productivity, and reduce cost per analysis.

LECO 744 Series

LECO 744 Series

Available Models

The 744 Series is available in multiple configurations to match your analytical needs:

- CS744 – Carbon and Sulfur Analyzer

- C744 – Carbon Analyzer

- S744 – Sulfur Analyzer

Key Features and Benefits

The 744 Series is engineered for robust performance, ease of use, and reliable long-term operation:

- High-frequency induction furnace for fast, consistent combustion

- 18 MHz, 2.2 kW RF induction furnace

- Rapid heating for reproducible sample oxidation

- Integrated oxygen lance

- Floods the crucible with high-purity oxygen

- Ensures complete combustion, even for difficult matrices

- Automation options for increased throughput

- Optional 10-sample and 60-sample autoloaders

- Supports extended, unattended operation

- High-velocity vacuum system

- Effectively contains dust and debris

- Helps maintain a clean analytical environment

- Improved infrared (IR) cell design

- Temperature-stabilized construction reduces sensitivity to ambient conditions

- Optimized emitter control and detection circuitry

- Enhanced long-term stability and extended IR cell lifetime

Theory of Operation

The CS744 carbon and sulfur analyzer is designed for wide-range determination of carbon and sulfur in metals, ores, ceramics, and other inorganic materials using combustion and non-dispersive infrared (NDIR) detection. The instrument is controlled by custom Cornerstone® software optimized for touch-screen operation.

A pre-weighed sample, typically around 1 gram, is combusted in a pure oxygen stream using RF induction heating. During combustion, carbon and sulfur in the sample are oxidized to carbon dioxide (CO₂) and sulfur dioxide (SO₂). The combustion gases are carried by the oxygen stream through a drying reagent and into the detection system.

Sulfur is first measured as SO₂ using an NDIR cell. The gas stream then passes through a heated catalyst, where carbon monoxide (CO) is converted to CO₂ and sulfur dioxide is converted to sulfur trioxide (SO₃), which is subsequently removed by a filter. Carbon is then measured as CO₂ using a second NDIR cell.

A pressure controller maintains constant pressure within the NDIR cells, minimizing interference caused by natural fluctuations in atmospheric pressure. An electronic flow sensor at the end of the gas stream continuously monitors carrier gas flow for diagnostic and system integrity purposes.

NDIR detection is based on the principle that CO₂ and SO₂ absorb infrared energy at characteristic wavelengths. The amount of absorbed IR energy is proportional to the gas concentration. Sample concentrations are calculated relative to calibration standards, with reference measurements of pure carrier gas performed prior to each analysis to reduce the impact of instrument drift and ensure accurate, reproducible results.