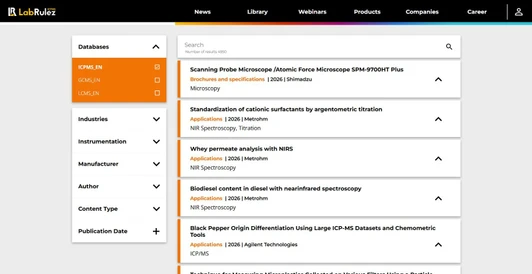

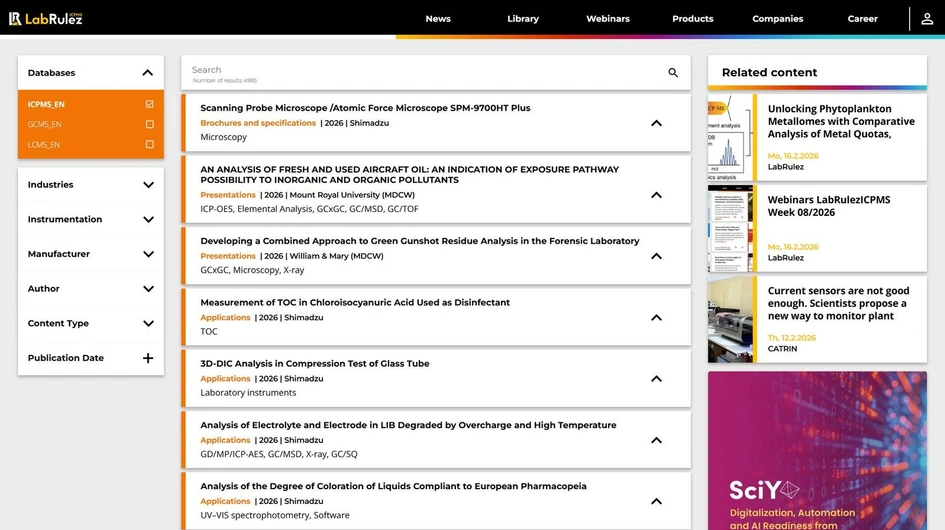

News from LabRulezICPMS Library - Week 08, 2026

LabRulez: News from LabRulezICPMS Library - Week 07, 2026

Our Library never stops expanding. What are the most recent contributions to LabRulezICPMS Library in the week of 16th February 2026? Check out new documents from the field of spectroscopy/spectrometry and related techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT SPECTROSCOPY/SPECTROMETRY RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezGCMS libraries.

This week we bring you application notes by Agilent Technologies, Metrohm, Shimadzu and Thermo Fisher Scientific!

1. Agilent Technologies: Quality Assessment of Saffron by UV‑Vis Spectroscopy in Accordance with ISO 3632

Integrated quantitative analysis using an Agilent Cary 3500 UV-Vis and Cary UV Workstation

- Application note

- Full PDF for download

Saffron is the world's most expensive spice, with its price per gram dependent on quality, origin, and purity. It is renowned for its vibrant color and distinctive flavor—attributes that contribute significantly to its culinary appeal. However, saffron's high market value and limited production make it vulnerable to adulteration, quality degradation, and mislabeling, all of which pose a risk to consumer health, safety, and trust.

Ultraviolet-Visible (UV-Vis) spectroscopy is a rapid, reliable analytical technique suitable for assessing spice quality by quantifying bioactive molecular markers. In saffron, crocin is the carotenoid compound responsible for color intensity, picrocrocin is the primary bittering agent, and safranal is the key contributor to aroma.

In this application note, we used an Agilent Cary 3500 UV-Vis spectrophotometer and Agilent Cary UV Workstation software to analyze a commercial saffron sample. The aim of the study was to grade the quality of the sample in accordance with ISO 3632-1:2025 and ISO 3632-2:2010 Spices — Saffron (Crocus sativus L.).1,2 These well-established industry standards provide specifications and test methods for the analysis of dried saffron, including filaments, cut filaments, and powder. The standardized test methods outlined in ISO 3632-2 support the classification and quality evaluation of saffron. The methods relate to the determination of moisture and volatile matter content (clause 7), crushing and sieving of samples for tests (clause 10), and the determination of the main characteristics using a UV-Vis spectrometric method (clause 14). Based on these evaluations and the quality criteria defined in ISO 3632-1:2025, saffron samples can be categorized into four commercial grades: Extra Class (EC), I, II, and III, with EC indicating the highest quality.

Experimental

Instrumentation

The blank cuvette and aqueous extract of sample cuvette were loaded in the Agilent Cary 3500 Multicell UV-Vis (Figure 1), which was operated using the parameters listed in Table 1. The instrument is powered by a xenon flash lamp that requires no warmup time and enables a full spectrum scan to be collected in under a second. The lamp includes a 10-year replacement warranty, minimizing the frequency and cost of replacement. The Cary 3500's modular design approach enables the spectrophotometer series to be configured towards varying sampling flexibility and scalability needs. For single sample applications and laboratories with reduced bench-space, the Cary 3500 Compact UV-Vis allows a user to measure a single sample and reference in ambient or temperature-controlled configuration. This application can also be conducted on the Cary 3500 Flexible UV-Vis, which has a larger-sized compartment for liquid and solid sample measurements, and for use with accessories.

Conclusion

The Agilent Cary 3500 Multicell UV-Vis spectrophotometer combined with Agilent Cary UV Workstation software provided precise quantification of color, taste, and aroma through the measurement of crocin, picrocrocin, and safranal compounds, respectively. The method supports the quality assessment of saffron in accordance with the ISO 3632 industry standard, enabling reliable grading of commercial samples while also flagging potential cases of adulteration, degradation, or mislabeling.

The Cary 3500 UV-Vis uses a reliable, long-lasting xenon flash lamp that requires no warmup time, allowing immediate operation and acquisition of full spectral scans for blank and saffron samples in under a second. These capabilities support high-throughput analysis of spices through the precise measurement of compound-specific absorbance peaks.

Using built-in spectral tools, automated calculations, and clear reporting features, the Cary UV Workstation significantly simplified the sampling-to-reporting workflow for saffron analysis. Customized calculations defined in ISO 3632 accelerate data processing and reduce calculation errors. The software also delivers results via a user-friendly interface, ideal for traceability.

Together, the Cary 3500 UV-Vis and Cary UV Workstation delivered significant time-savings by minimizing time spent analyzing data and allowing more time for quality assurance of samples. The Cary 3500 system provides an efficient solution for the determination of the main characteristics saffron in accordance with clause 14 of ISO 3632-2:2010.

2. Metrohm: Feed analysis with near-infrared spectroscopy (NIRS)

Simple, fast multiparameter determination of animal feed

- Application note

- Full PDF for download

Livestock production is a complex process involving many independent and integrated operations. According to the World Health Organization (WHO), the foundations for successful livestock production are the availability of animal feed and efficient feeding. Quality control (QC) of feed and feed ingredients is crucial to ensure the production of safe and nutrient-rich animal feed. Typical QC parameters measured during the production of feed are fat, moisture, protein, fiber, ash, and starch. However, analyzing these parameters is usually done with wet chemistry, requiring different time-consuming procedures, complex analysis methods, and costly chemical reagents. Near-infrared spectroscopy (NIRS) offers rapid and reliable prediction of fat, moisture, protein, fiber, ash, and starch content of different feed types in a few seconds without any sample preparation.

EXPERIMENTAL EQUIPMENT

Around 500 samples of feed (e.g., for poultry, swine, cattle, goats, and sheep) were analyzed on a Metrohm NIR Analyzer. All measurements were performed in reflection mode using the large cup. The samples were measured in rotation to collect spectral data from several areas. Spectral averaging of signals from various spots helped to reduce influences from sample inhomogeneity. Metrohm software was used for all data acquisition and prediction model development.

CONCLUSION

This Application Note demonstrates the feasibility to determine multiple key quality parameters of feed with NIRS analysis. Several analytical methods are usually required to measure starch, ash, fiber, protein, moisture, and fat in animal feed (Table 4). NIR feed analysis offers an easier alternative with high accuracy and real-time results.

3. Shimadzu: Online TOC Measurement for Ultra-pure Water in Semiconductor Industries

- Application note

- Full PDF for download

User Benefits

- Enables stable measurement of ultra-pure water with TOC concentrations below 1 μg/L.

- The large color touch panel and compact body make operation easy.

- The Active-Path structure, which integrates the lamp and sample flow path, enables high oxidation performance.

The semiconductor manufacturing process involves various stages such as wafer production, film formation, photolithography, etching, and resist stripping, each of which involves cleaning steps. Even minimal contamination on the semiconductor surface can impact product quality and yield, making it crucial to effectively remove dirt and impurities during cleaning. For this reason, the purity of the cleaning water used in these cleaning processesis extremely important. The recent trend towards ever-smaller, higher-capacity semiconductors means that ultra-pure cleaning water, thoroughly free of organic and other impurities, has become essential.

Typically, ultra-pure water is produced by first purifying tap or groundwater to produce pure water, and then further refining it into ultra-pure water. Impurities in water include organic and inorganic substances, particles, as well as microorganisms. Various methods, such as activated carbon filters, reverse osmosis (RO) membranes, ultraviolet lamps, and ion exchange resins, are used in combination to purify water into ultra-pure water.

Maintaining the quality of ultra-pure water used for semiconductor cleaning is critical. The online TOC analyzer for ultra-pure water, TOC-1000e S (Fig. 1), enables highly sensitive TOC measurement with a detection limit of 0.02 μg/L using UV oxidation and conductivity measurement methods. This application presents the features and functions of the TOC1000e S, along with examples of online measurements of ultrapure water.

Features of TOC-1000e S

The TOC-1000e S is an ultra-compact device that can be installed on a tabletop, wall, or pole mount. The front panel features a large color touch panel that is highly visible even in dark environments, enabling easy operation. An excimer lamp (mercury-free) that emits high-energy ultraviolet light with a wavelength of 172 nm is used as the light source for the oxidation section. To ensure the oxidation of organic compounds, TOC-1000e S uses a unique structure called Active-Path, which integrates the excimer lamp and the sample flow channel. In a typical ultraviolet irradiation section, an air gap between the lamp and the sample flow channel results in inefficient ultraviolet light transmission and the generation of ozone within the device. However, in Active-Path, a sample flow path within the light-emitting part enables efficient irradiation of the sample with ultraviolet light while preventing ozone generation (Fig. 2).

Conclusion

TOC-1000e S enables the monitoring of TOC of ultra-pure water used in semiconductor manufacturing. The compact body and user-friendly interface assist usersin their routine operations.

4. Thermo Fisher Scientific: Analyzing SiC/Co materials for radar absorption and EMI shielding using ARL X’TRA Companion XRD

- Application note

- Full PDF for download

SiC–Co composites represent a new class of engineered materials designed to combine dielectric and magnetic loss mechanisms for effective absorption of electromagnetic radiation. By dispersing cobalt or cobalt ferrite phases within a silicon carbide or SiOC matrix, these composites achieve tunable permittivity and permeability, enabling efficient impedance matching across radar and microwave frequencies. For defense and aerospace applications, where low radar cross section and stable electromagnetic shielding are critical, such composites are attractive because they also retain thermal and mechanical stability beyond the capabilities of polymer-based absorbers.

X-ray diffraction (XRD) plays a central role in the development and quality control of these materials. It allows unambiguous identification of SiC polytypes that influence dielectric behavior, while simultaneously detecting cobalt, cobalt oxide, or ferrite phases that govern magnetic response. XRD quantification provides insight into crystalline-to-amorphous ratios, crystallite size, and micro strain directly linked to electromagnetic performance and high-temperature durability. By correlating phase composition with measured S-parameters, researchers can optimize absorber formulations and processing conditions to achieve reliable, broadband EMI shielding.

Instrument & software

The Thermo Scientific™ ARL™ X’TRA Companion X-Ray Diffractometer (c.f. Figure 1) is a simple, easy-to-use benchtop instrument for routine phase analysis as well as more advanced applications. The ARL X’TRA Companion XRD uses a θ/θ goniometer (160 mm radius) in Bragg-Brentano geometry coupled with a 600 W X-ray source (Cu or Co). The radial and axial collimation of the beam is controlled by divergence and Soller slits, while air scattering is reduced by a variable beam knife. An integrated water chiller is available as an option. Thanks to the state-of-the art solid state pixel detector (55x55 μm pitch), the ARL X’TRA Companion XRD provides very fast data collection and comes with single-click Rietveld quantification capabilities and automated result transmission to a LIMS (Laboratory Information Management System) seamless integrated into Thermo Scientific™ SolstiX™ Pronto instrument control software.

Your benefits

The ARL X’TRA Companion XRD system delivers high-quality data in 10 minutes, enabling phase quantification, reliable identification of SiC polytypes, and advanced interpretation of anisotropic micro strain in Co. With the PONKCS method, the amorphous fraction can be quantified accurately. These structural insights directly link to physical properties such as dielectric–magnetic balance, EMI shielding efficiency, and radar absorption performance, providing a basis for fine-tuning materials to application needs.