News from LabRulezICPMS Library - Week 07, 2026

LabRulez: News from LabRulezICPMS Library - Week 07, 2026

Our Library never stops expanding. What are the most recent contributions to LabRulezICPMS Library in the week of 9th February 2026? Check out new documents from the field of spectroscopy/spectrometry and related techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT SPECTROSCOPY/SPECTROMETRY RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezGCMS libraries.

This week we bring you application notes by Agilent Technologies, Metrohm, Shimadzu and Thermo Fisher Scientific!

1. Agilent Technologies: Black Pepper Origin Differentiation Using Large ICP-MS Datasets and Chemometric Tools

Elemental profiling using an Agilent 7850 ICP-MS and Agilent Mass Profiler Professional (MPP) software

- Application note

- Full PDF for download

Black pepper’s high value and global demand are drivers for economically motivated adulteration, a fraudulent practice that can pose public health risks. Because black pepper is most often sold in ground, crushed, or mixed forms, its supply chain is difficult to monitor and manage. Also, consumer campaigns against deforestation and the European Union Regulation on Deforestation-free (EUDR) products have increased calls for greater sourcing transparency. Products with a known geographical indication can demand a higher price. Companies do not want to become implicated in false claims about the sourcing of products, and many are keen to have full visibility of their products’ origin. To address this need, the European Commission has established the Protected Geographical Indication (PGI) system to protect regional specific products, thereby promoting their unique characteristics based on geographical origin and traditional competence of production. The PGI scheme has increased the demand for detailed information regarding the geographical source of food products, a trend that is likely to continue as EUDR is implemented across the EU and associated markets. Verifying the geographical origin of black pepper using elemental fingerprints is highly relevant to protecting value chain stakeholders, ensuring both quality and traceability while upholding the principles of food integrity.

Several analytical methods can be used for profiling certain elements in foods. However, inductively coupled plasma mass spectrometry (ICP-MS) is unique because of its rapid throughput, multi-element capability, ultratrace sensitivity, isotopic analysis, versatility across sample types, low sample volume requirements, compliance with regulatory requirements, and low cost.3

The Agilent 7850 ICP-MS is equipped with an Octopole Reaction System (ORS4 ), a collision/reaction cell (CRC) that uses helium (He) gas and Kinetic Energy Discrimination (KED) to remove polyatomic interferences on key analytes.4 If left unchecked, these interferences can affect data accuracy in complex food products. The integration of the 7850 with Agilent ICP-MS MassHunter software streamlines data analysis. When integrated with chemometric analysis, ICP-MS demonstrates high precision in multi-elemental profiling of diverse food matrices, effectively distinguishing their geographical origin.5

In this study, 150 black pepper samples from five countries (Brazil, Cambodia, India, Indonesia, Vietnam) were analyzed using the 7850 ICP-MS to obtain elemental fingerprints of the samples. Agilent Mass Profiler Professional (MPP) software was used to process the ICP-MS elemental data and to construct chemometric models for distinguishing the geographical origin of the samples, as adapted from Chilaka et al.5

Experimental

Instrumentation

An Agilent 7850 single-quadrupole ICP-MS was used for the analysis of 38 elements in the black pepper samples. Sample introduction was performed via a peristaltic pump connected to an Agilent MicroMist nebulizer and an Agilent SPS 4 autosampler. All elements were measured using helium collision (He KED) mode, except for boron (B), which was analyzed in no gas mode. Instrument control was performed using Agilent ICP-MS MassHunter 5.1 software, and data processing was conducted using Agilent MPP software, version 15.1. Instrument operating conditions as shown in Table 1.

Conclusion

This study investigated the potential of ICP-MS elemental profiling coupled with chemometric analysis for geographical origin discrimination of black pepper samples from five countries, including Brazil, Cambodia, India, Indonesia, and Vietnam. A total of 38 elements was measured in 150 black pepper samples using the Agilent 7850 ICP-MS. Chemometric analysis was performed on the ICP-MS elemental data using Agilent Mass Profiler Professional (MPP) software. The PCA analysis exhibited satisfactory reliability and classification rates and demonstrated potential for the authentication of the geographical origin of black pepper. However, the separation of the Cambodian and Vietnamese samples was less distinct than the other groups, revealing potential similarities in elemental profiling between the bordering countries, which share similar climatic, geological, and agricultural conditions. Using LDA and RF classification models on the black pepper test set, we achieved a high overall accuracy in determining the geographical origin of the samples. These findings provide empirical support for the combined use of elementomics and chemometric techniques in black pepper authentication, contributing to fraud prevention. The study also demonstrates the potential of the method for application to other food types.

2. Metrohm: Milk powder analysis by near-infrared spectroscopy

Determination of moisture, fat, lactose, and protein content

- Application note

- Full PDF for download

For milk powder producers, final product control is essential to meet strict regulatory standards, guarantee comprehensive quality assurance, ensure consistent nutritional quality, and extend shelf life. These are all especially important for infant formula and dairy ingredients used in sensitive applications. Near-infrared spectroscopy (NIRS) is a fast, reagentfree method for measuring key quality parameters such as moisture, protein, lactose, and fat content directly in milk powder. The NIRS solution requires no sample preparation, enabling real-time monitoring either in the lab or directly on the production line. This allows producers to react quickly to process variations, minimize waste, and maintain product integrity batch after batch.

EXPERIMENTAL EQUIPMENT

More than 600 samples of powdered milk from different suppliers were analyzed on an OMNIS NIR Analyzer (Figure 1). The different milk powders were placed into an OMNIS sample cup and analyzed in diffuse reflection mode. To include sample variety, the sample rotated during measurement to collect spectra from different locations. The automatically averaged spectra were used for model development. Reference values were obtained by official methods, e.g., AOAC 927.05 (moisture), AOAC 939.02 (protein), and AOAC 932.06 (fat). For the lactose content determination, a phenol-sulfuric acid method was used.

CONCLUSION

This Application Note presented the analysis of milk powder using NIR spectroscopy. Models for several quality parameters (fat, protein, lactose, and moisture content) were created. Independent validation samples confirmed the robustness and reliability of the models, with high correlation coefficients and low prediction errors achieved across all parameters. Notably, the dataset included samples from diverse global origins, capturing a broad range of product variability. This study shows that NIRS can be successfully integrated into the quality control workflow for dairy powder analysis.

3. Shimadzu: Analysis of Electrolyte and Electrode in LIB Degraded by Overcharge and High Temperature

- Application note

- Full PDF for download

User Benefits

- ICP-AES enables accurate quantification of cathode material dissolved in electrolytes.

- GC-MS assesses degradation from components in electrolytes with unknown usage.

- EDXRF easily evaluates transition metals, phosphorus, fluorine, and other elements deposited on electrodes

When lithium-ion batteries are used in EVs or ESS applications, numerous cells are connected in series and parallel to form modules, and multiple modules are further connected to construct a pack. In such configurations—where many cells are connected in series—the state of charge of individual cells varies, as shown in Figure 1. Moreover, because the cells are densely packed to reduce volume, the ambient temperature experienced by each cell also varies. In this application, we conducted cycle tests under overcharged or high-temperature conditions, disassembled the degraded pouch cells, and analyzed both the electrolytes and the electrodes.

Analysis of electrolyte and electrode

Electrolytes and electrodes were extracted from the batteries degraded through the cycle tests (hereafter referred to as “degraded cells”) and analyzed using the instruments shown in Figures 3–5. It is known that electrolytesin degraded cells contain transition metals (Ni, Co, Mn) dissolved from the cathode active material1). In addition, electrolyte solvents are known to generate characteristic degradation products as deterioration progresses2). By analyzing these degradation-related elements and compounds, the degradation state of the battery can be assessed. In this article, we propose a multifaceted evaluation of electrolytes using ICP-AES and GC-MS. On both the cathode and anode, insulating layers known as CEI/SEI form on the electrode surfaces. Under improper charging conditions, excessive formation of these layers can lead to capacity loss. Furthermore, the dissolved metals from the cathode deposit and precipitate on the anode. These deposits can cause internal short circuits, posing risks such as fire hazards. While such electrode conditions are typically evaluated by ICP-AES or XPS to examine elemental content or surface chemical states, this article introduces a simpler evaluation method using EDXRF.

Summary

Analysis of the electrolytesfrom degraded batteries using ICP-AES and GC-MS revealed dissolution of transition metals as well as the formation of degradation products. Furthermore, EDXRF analysis of the electrodes enabled straightforward detection of changesin elemental composition, including transition metals, fluorine, and phosphorus. These analytical techniques allow for a multifaceted evaluation of battery degradation. In real-world battery operation, fluctuations in charging conditions and ambient temperature introduce variability in degradation states. By assessing degradation mechanisms individually, as demonstrated in thisreport, it is possible to obtain insights that contribute not only to improving intrinsic battery performance but also to optimizing implementation methods and control conditions.

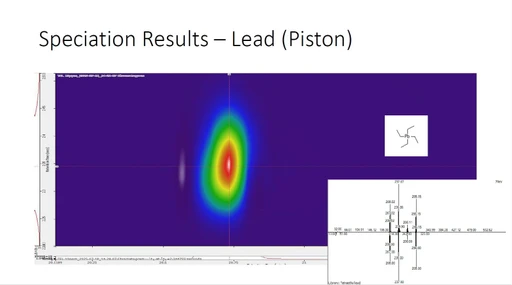

4. Thermo Fisher Scientific: Analyzing Spinel refractory MgO-Al2O3 premix using ARL X’TRA Companion XRD

- Application note

- Full PDF for download

Spinel refractories—primarily magnesia–alumina (MgAl₂O₄)— are the workhorses of high-temperature linings in steel ladles, cement rotary kilns, glass tanks, and non-ferrous smelters. Their appeal lies in a combination of shock resistance, chemical stability against basic slags, and an expansion behavior that mitigates cracking. Depending on the duty, they are used as bricks, castables, or gunned repairs, sometimes with engineered microstructures that blend spinel with periclase, corundum, or zirconia to tune creep, corrosion, and spalling performance.

X-ray diffraction (XRD) underpins manufacturing control from raw mix to fired product. During synthesis, XRD tracks the solid-state reaction of MgO and Al₂O₃ into spinel, verifying the disappearance of periclase and alumina and quantifying the spinel fraction by Rietveld analysis. Lattice parameters reveal cation stoichiometry and solid-solution effects; peak breadth trends indicate crystallite growth and microstrain, proxies for sintering progress. In finished components, XRD detects secondary phases such as calcium aluminates introduced by binders, slags, impurities, and it provides fingerprinting for batch-to-batch consistency after thermal exposure. Embedded into routine QA/QC, XRD shortens feedback loops, stabilizes recipes, and links processing conditions to the microstructure that governs refractory life.

Instrument & software

The Thermo Scientific™ ARL™ X’TRA Companion X-Ray Diffractometer (c.f. Figure 1) is a simple, easy-to-use benchtop instrument for routine phase analysis as well as more advanced applications. The ARL X’TRA Companion uses a θ/θ goniometer (160 mm radius) in Bragg-Brentano geometry coupled with a 600 W X-ray source (Cu or Co). The radial and axial collimation of the beam is controlled by divergence and Soller slits, while air scattering is reduced by a variable beam knife. An integrated water chiller is available as an option. Thanks to the state-of-the art solid state pixel detector (55x55 μm pitch), the ARL X’TRA Companion provides very fast data collection and comes with single-click Rietveld quantification capabilities and automated result transmission to a LIMS (Laboratory Information Management System) seamless integrated into Thermo Scientific™ SolstiX™ Pronto instrument control software.

Your benefits

The ARL X’TRA Companion XRD workflow delivers answers in minutes, quantifying MgO, α-Al₂O₃, and MgAl₂O₄ while resolving Ca–Si silicates and trace Fe-spinels. Subtle differences between corundum and spinel are cleanly separated, and LOI drivers—carbonates, brucite, and Mg-sulfates—are identified and trended. These insights let you compute spinel potential, anticipate pore-closing expansion, and set the right pre-dry / prefire schedule to avoid spalling. You can clearly distinguish mid-grade, ore-derived feeds from premium low-silica materials, tighten incoming QA, and optimize formulations for cement/lime kilns, tundish linings, and other carbon-free basic applications.