Fluorite ore recognition using spectral clustering and smartphone digital images calibrated with a ColorChecker: A case study at the Lújar underground mine, Spain

Minerals Engineering, Volume 232, 2025, 109514: Fig. 14. Flowsheet for fluorite grade recognition based on pellet images properties.

The goal of this study is to develop an efficient and low-cost method for recognizing fluorite ore grade using smartphone images and spectral clustering. By photographing pellet samples derived from drilling chips and correcting image colors with a ColorChecker, the method ensures consistency under variable lighting conditions. Principal component analysis of color and texture data is used to build clustering models that can discriminate between ore qualities.

This approach provides a reliable screening tool, especially effective in identifying waste material with up to 94.74% accuracy using spectral clustering. Unlike previous methods, it does not require expensive cameras or skilled operators, making it particularly beneficial for small- and medium-sized mining companies. The method supports more accessible ore classification and opens the door to broader applications in mine planning, processing, and quality assessment.

The original article

Fluorite ore recognition using spectral clustering and smartphone digital images calibrated with a ColorChecker: A case study at the Lújar underground mine, Spain

Enming Li, Pablo Segarra, José A. Sanchidrián, Santiago Gómez, Luis Iglesias, Alberto Fernández, Rafael Navarro

Minerals Engineering, Volume 232, 2025, 109514

https://doi.org/10.1016/j.mineng.2025.109514

licensed under CC-BY 4.0

Selected sections from the article follow. Formats and hyperlinks were adapted from the original.

With the advancement of portability, connectivity and camera resolution of smartphones, they have been widely applied across numerous image analysis domains, such as the segmentation of images (Campos-Taberner et al., 2016), digital image colorimetry (Fan et al., 2021) and photomicrograph acquisition (Roy et al., 2014); the smartphone seems to be a suitable “low cost” replacement for a professional photography device to procure the color information from the tasks of ore grade estimation. This study proposes a smartphone as photography device to procure fluorite-based pellet images, to be analyzed for fluorite grade recognition and prediction. In order to overcome the variations in lighting conditions which may critically introduce noise or inconsistencies in image colors, this study proposes to employ a ColorChecker (Pascale, 2005) that allows correcting the colors of pellet images to obtain the genuine color of each pixel. Significant color characteristics are extracted from the corrected pellet images and used for predicting the fluorite grade by a simple unsupervised machine learning technique. As a background for this approach, the authors demonstrate that color information of images of in-borehole walls drilled in the same mining site are sensitive to the fluorite content that it is predicted with reasonable accuracy (Li et al., 2023).

2. Data overview

Drilling chips of production blastholes and exploration boreholes from Lújar mine (F-Pb-Zn) were collected while drilling for grade control purposes. The Lújar mine is an underground mine, located in Granada (southeast of Spain). It mainly extracts fluorite, often accompanied by lead (in the form of galena) or zinc (in form of sphalerite or smithsonite). It is a Mississippi Valley Type (MVT) stratabound deposit hosted in the carbonate sequences of the Ladinian (Upper Triassic), mainly composed of dolomites but also limestones as gangue. Geologically, it belongs to the Alpujarride Complex (Internal Zones of the Betic Chain) (Amor et al., 2019). The samples are quartered, dried, grinded to a size below 80 μm, and further quartered to obtain a 10 g sample from which pressed powder pellets of 32 mm of diameter and 5 mm height with particles than 80 μm are prepared. The pellets were analyzed in the mine laboratory with an X-Ray Fluorescence (XRF) spectrometer by Thermo Fisher Scientific, model ARL OPTIM'X WDXRF with a Rhodium anode X-ray tube (50 kV, 150 mA) and LiF200, InSb and AX06 analyzer crystals, using the Oxsas 2.2 software. That device provides an elemental composition from which the amount of calcium fluoride, calcium carbonate, calcium magnesium carbonate (dolomite), silica, ferric oxide, aluminum oxide, zinc and lead are obtained by stoichiometric calculations.

A dataset composed by 494 pellets from Lújar underground mine is considered in this work. 198 and 296 samples were collected from levels 70 and 345, respectively, during 2020 and 2021. The distributions of the main chemical compounds of the pellets are shown in Fig. 1; the kernel density estimate (Holger, 2015) of the probability density (grey patch) is overlapped with the box-and-whisker diagram. Fluorite (CaF2), limestone (L) and dolomite (D) are predominant (left graph), while the oxides are less abundant (right graph, note the different Y-axis scale). The pellets are dolomite-rich in general, with a fluorite content below 20 % in most of the cases. Pellets with fluorite as predominant compound are scarce (see blue dots in the fluorite distribution, left graph, Fig. 1), while fluorite is less than 3.6 % in 124 pellets (a 25 % of the total) that are rich in either dolomite or limestone. This reflects the chemical composition of the deposit, with typical grades in the order of 15 % in fluorite, complicating the in-situ ore recognition (Amor and Navarro, 2016). Silica is the predominant oxide in the pellets (see right graph), with a 75 percentile of 6.5 %. The amount of the other oxides is in general smaller, though in some pellets they are atypically high which could affect to the color. There are also traces of zinc and lead, lower than 1.5 % in 95 % of the pellets; for pellets with a large lead (>30 %) amount, the color becomes dark (i.e. greyish-black).

The pellets were photographed with a smartphone with a resolution up to 50 Mpx following the layout in Fig. 2. Sunlight was used as the light source. The pellets were placed with the clean side (i.e. opposite to the damaged one by the X-Ray beam) towards the camera. Taking pictures can be voice-activated to avoid the movement of camera. Some camera settings like the shutter speed value (1/30 s), the aperture (f/1.85), and the focal length (6.67 mm) are constant, while the exposure time or the ISO are automatically tuned by the smart phone. They are in the range 1/451 – 1/98 s for exposure time and 50 – 160 for ISO, with mean values of 1/141 s and 50 respectively. The images are recorded in “jpg” format. Variations in the camera settings and in the light intensity distort the pellet colors in the images. To assess these errors and correct them, a low-cost 24 patch ColorChecker Classic Mini target (63.5 × 109.0 mm) manufactured by “X-Rite” was placed on the top part of the image in the same relative position with respect to the pellet. The ground sampling distance is 0.0687 mm. A standardized television test card, i.e., PM5544-PAL, is used to ensure diverse background colors and facilitate the automatic detection of the ColorChecker. This background has the advantage that it is easily reproducible, but since was in-house printed still makes necessary a color reference card (e.g. ColorChecker) to control the image colors under any illumination. Similar test cards than PM5544-PAL, will likely have a similar performance, while other tested backgrounds, like a black cardboard, hinder the detection of the patches of the color reference card.

Minerals Engineering, Volume 232, 2025, 109514: Fig. 2. Experimental layout of taking the fluorite-based pellets and color correction by a Colorchecker.

Minerals Engineering, Volume 232, 2025, 109514: Fig. 2. Experimental layout of taking the fluorite-based pellets and color correction by a Colorchecker.

2.2. Features extraction

Various color parameters are calculated, however, only a few parameters have stronger correlation with the fluorite grade and thus selected to develop the model. The pixel color intensities (PCIs) of the corrected photos of the ROI of each pellet are described with the mean of the red, green and blue intensities of the pixels, that are abbreviated as avR, avG and avB, respectively. The resulting distributions are shown in Fig. 6; mean red intensities range from 0.85 to 0.55 while blue intensities are the smaller ones, down to 0.3. A comparison of the median of each color channel before and after correction (green versus red horizonal lines, respectively), indicates the color shift towards slightly darker colors. The Blue Flower patch (P5) stays now inside the 99 % coverage of the mean intensities together with the Light Skin (P2), Neutral 8 (P20), and Neutral 6.5 (P21) patches. Mean green intensities are strongly correlated with the mean of the red and blue intensities with Spearman coefficients of 0.88 and 0.98, respectively and are discarded as an input for predicting fluorite grade.

Minerals Engineering, Volume 232, 2025, 109514: Fig. 6. Violin and box plots of the descriptor parameters of the images of the ROI of the pellets: mean of red, green and blue intensities (avR, avG, avB, respectively), uncertainty (U) and texture-correlation (Tc); note that all the parameters are non-dimensional. The circular markers show the colors of the patches lying within the 99 % coverage of the mean color intensities. The green horizontal lines are the median of the pixel intensities of ROI in raw pellet images. (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.)

Minerals Engineering, Volume 232, 2025, 109514: Fig. 6. Violin and box plots of the descriptor parameters of the images of the ROI of the pellets: mean of red, green and blue intensities (avR, avG, avB, respectively), uncertainty (U) and texture-correlation (Tc); note that all the parameters are non-dimensional. The circular markers show the colors of the patches lying within the 99 % coverage of the mean color intensities. The green horizontal lines are the median of the pixel intensities of ROI in raw pellet images. (For interpretation of the references to color in this figure legend, the reader is referred to the web version of this article.)

The dispersion in the color clouds for each pellet in the RGB space is described with the standard deviational ellipsoid (SDE), which is extensively applied to investigate uncertainty of datasets in 2D and 3D spaces (Yang et al., 2020). The SDE is calculated with the covariance matrix of the PCIs under the assumption that the data comes from a normal distribution using the MATLAB function error_ellipse defined by Johnson (2023) (A.J., 2023). Its major axis indicates the direction of largest variability, and the scatter in PCIs is taken as the length of the major semi axis. This single parameter describes the uncertainty (U) in the PCIs and is used instead of the standard deviation, or other dispersion measurements, of the color pixel intensities.

Fig. 7 shows, as an example, the color intensities of a pellet in the RGB space and the SDE at a 95 % confidence level. This ellipsoid is representative of the uncertainty observed in the rest of the pellets; it is elongated with the major axis significantly longer than the other two having an angle with the green axis of 46.3° sd 1.0°, and an inclination with respect to the blue axis of 54.2° sd 1.6 (mean and standard deviation from all the pellets). The major semi-axis with a length of 0.0895 is close to the median uncertainty of all pellets, and it lumps mainly dispersion in the red and blue colors. The minor semi axes are both about 0.0168.

![]() Minerals Engineering, Volume 232, 2025, 109514: Fig. 7. Color pixel intensities in the normalized RGB space of the ROI of the corrected image of pellet 37,711 and its 95 % confidence SDE; the size of the points is proportional to their relative probability.

Minerals Engineering, Volume 232, 2025, 109514: Fig. 7. Color pixel intensities in the normalized RGB space of the ROI of the corrected image of pellet 37,711 and its 95 % confidence SDE; the size of the points is proportional to their relative probability.

5. Conclusions

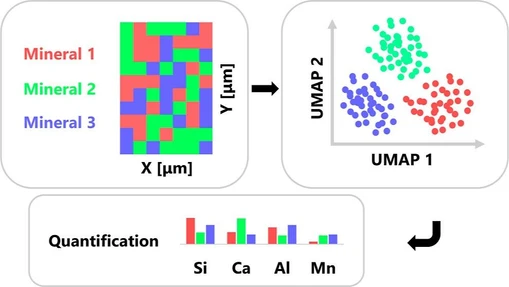

In this study, a smartphone with a high-resolution camera is employed to procure photographs of pellets made from finely ground (below 80 μm) and compacted drilling chips samples. As a novelty, a standard color reference card is placed next to the pellets to obtain the non-lighting-interfered ore colors independently of the light conditions. Image-based analysis is integrated with clustering algorithms. Three clusters are generated according to the three principal components obtained from the color properties, namely mean of red and blue pixel color intensities (PCIs), uncertainty in PCIs, and texture-correlation. The precision for each cluster is calculated from the chemical analysis of the pellets and cluster C2 could be assigned to waste with high occurrence probability and cluster C1 to ore. The lower precision from this cluster makes it necessary to consider chemical analysis if the pellets are clustered in this cluster. However, if the color attributes of the pellets correspond to cluster C3, the pellets could be deemed as waste with an excellent precision, close to 95 %. Such results enable a fast and cheap screening criterion of pellets. Hence lowering grading costs, increasing equipment availability, and reducing maintenance costs by extending the average lifespan of the X-ray tube.

Compared with previous studies, the image-based recognition procedure proposed here is a low-cost technique that does not requires a rigid operational environment, nor high-professional skills. Neither the image processing nor the spectral clustering add computational difficulties, and the entire process can be easily applied to other ores that exhibit distinct colors corresponding to variation in their mineral composition and concentrations. Though not complete substituting geochemistry analysis, these research opens the way to use smartphone images to assess ore grading in the different stages of the mining cycle, from modeling of deposits to mineral processing. This will contribute to decrease resources and cost dedicated to these tasks, enabling ore-grading for cases with resources limitations.