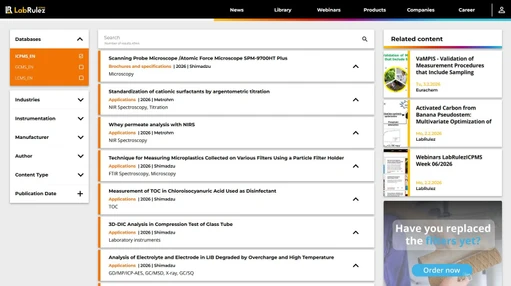

News from LabRulezICPMS Library - Week 02, 2026

LabRulez: News from LabRulezICPMS Library - Week 02, 2026

Our Library never stops expanding. What are the most recent contributions to LabRulezICPMS Library in the week of 5th January 2026? Check out new documents from the field of spectroscopy/spectrometry and related techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT SPECTROSCOPY/SPECTROMETRY RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezGCMS libraries.

This week we bring you application notes by Agilent Technologies, Metrohm and Waters Corporation!

1. Agilent Technologies: Multi-Elemental Analysis of Lithium Aluminum Titanium Phosphate by Automated ICP-OES

Assay of all-solid-state Li-ion battery electrolytes by Agilent 5800 ICP-OES with ADS 2 autodilutor

- Application note

- Full PDF for download

Rising global electricity demand and the shift away from fossil fuels are driving developments in the cleaner energy and energy storage sectors. Among the emerging energy storage technologies, all-solid-state batteries (ASSBs) are attracting attention due to their enhanced safety, higher energy density, and improved performance relative to conventional lithium-ion batteries (LIBs). Current research is largely focused on optimizing the electrolyte composition of ASSBs, which use a solid electrolyte in place of the liquid or gel electrolyte found in conventional LIBs.

Various properties of lithium aluminum titanium phosphate (LATP) make it suitable as a solid electrolyte material for use in ASSBs.1 It has high ionic conductivity (reaching 10–⁴ to 10–³ S/cm at room temperature, close to or exceeding some liquid electrolytes), which improves battery charging and discharging efficiency.

Compared to sulfide-based solid electrolytes, LATP is more chemically stable in air and water, minimizing the requirement for an inert atmosphere during processing. This property simplifies manufacturing and reduces costs of storage and transportation. LATP is compatible with high-potential (5 V) cathode materials such as LiNiCoMnO2 (NMC), improving cell energy density. It also offers excellent mechanical strength and ease of processing, allowing it to be shaped into thin films that support miniaturization and robust battery design. The accurate determination of major, doping, and trace elements in materials such as LATP is important at all stages of development, from R&D to pilot-scale production and full-scale manufacturing. The ratio of major elements to doping elements significantly affects the ionic conductivity and stability of lithium (Li) ions, while trace impurities can compromise stability and mechanical strength. Elemental impurities can accumulate during battery charging/ discharging cycles, leading to battery performance degradation, such as shortened cycle life, reduced efficiency, or potential safety risks. Multi-elemental analysis of battery precursors like LATP is therefore vital for ensuring the overall quality of ASSBs.2

Battery scientists also require methods to analyze the elemental composition of spent electrolytes to investigate changes that occur during charge and discharge cycles. These analyses support the production of consistent and reliable materials, promoting technological advancement and enabling the industrial implementation of ASSBs.

Inductively coupled plasma-optical emission spectroscopy (ICP-OES) is widely used for the simultaneous measurement of multiple elements in complex samples, due to its speed, stability, and tolerance to high total dissolved solids (TDS). Samples with elevated concentrations of matrix elements are classified as high TDS. These samples can pose several analytical challenges for ICP-OES, including spectral interferences from overlapping emission lines, plasma instability, signal drift, and increased maintenance. However, these challenges can be managed or avoided using fieldproven instrumentation. The Agilent 5800 Vertical Dual View (VDV) and 5900 Synchronous Vertical Dual View (SVDV) ICP-OES instruments have seen widespread adoption throughout the LIB value chain, effectively addressing the diverse analytical requirements of the industry.3

In a recent study, the 5800 VDV ICP-OES was used for the quantitative analysis of the matrix elements in a Lithium Lanthanum Zirconate Tantalum sample, another all-solidstate electrolyte material.4 The 5800, which uses a robust vertical torch, SSRF generator, Cooled Cone Interface, and is engineered without moving optical components, ensured excellent stability and no maintenance-related interruptions during the analysis.5

Experimental

Instrumentation

The Agilent ICP-OES Automation System was used for the analysis of the LATP sample digests (Figure 1). The Agilent 5800 VDV ICP-OES was equipped with a MiraMist nebulizer, inert spray chamber, and a fully demountable torch assembly with a 1.8 mm id injector. The Agilent ADS 2 in-line autodilutor was used for the automatic preparation of calibration standards and autodilution of samples. Details of the operation and capabilities of the ADS 2 can be found elsewhere.10 Following preparation, the standards and samples were delivered to the ICP-OES by the Agilent SPS 4 autosampler.

Conclusion

A highly automated ICP-OES method was developed for the simultaneous measurement of four major elements and 16 minor and trace elements in lithium aluminum titanium phosphate (LATP) solid electrolyte samples. The samples were acid digested using microwave-assisted digestion and then analyzed using an Agilent ICP-OES Automation System. The automated system comprised an Agilent 5800 VDV ICP-OES with integrated AVS 7 switching valve coupled to an ADS 2 intelligent dilution system, all controlled by Agilent ICP Expert Pro software.

The ADS 2 automatically prepared the calibration standards from two stock solutions, accelerating the preparation process, reducing analyst workload, and minimizing labware usage. Calibration curves with correlation coefficients above 0.999 for all elements were autogenerated.

MDLs below 1 mg/kg were achieved for most of the trace elements in the sample. Recoveries of all 16 trace elements spiked at both 0.2 mg/L (1.0 mg/L for Mg) were between 91 and 107%, confirming the accuracy of the method. The instrument displayed excellent stability during the analysis of the four matrix elements in the actual LATP samples over two hours, with data fluctuation below 1%.

The automated quantitative ICP-OES method supports R&D and QA/QC by detecting impurities like Fe, Mg, and Na, while also measuring Li, Al, Ti, and P in the same run. Ensuring the quality of LIB-electrolyte materials is important to meet desired performance targets, enhance safety, and extend the longevity of solid-state batteries.

2. Metrohm: Quality control of honey with NIR spectroscopy

Simultaneous determination of color and glucose, fructose, sucrose, maltose, and turanose content with results in seconds

- Application note

- Full PDF for download

Honey is mainly comprised of the sugars glucose and fructose, which make up to 85% of its total weight. It additionally contains sucrose, a disaccharide composed of fructose and glucose, and other disaccharides such as maltose and turanose—present in concentrations from 0.5 to 3.5% [1]. The sugar content of honey is usually measured with high performance liquid chromatography (HPLC). Honey's color is a quality attribute evaluated by consumers and is an important sensory property in the beekeeping market. Internationally, different types of honey are classified using the Pfund color scale. All of these honey quality parameters can be measured simultaneously in just a few seconds without any sample preparation using near-infrared spectroscopy (NIRS).

EXPERIMENTAL EQUIPMENT

Pure honey samples were measured with an OMNIS NIR Analyzer Solid (Figure 1). All measurements were performed in transflection mode (1000–2250 nm) using a 2 mm gap size reflector and 28 mm disposable vials. OMNIS Software was used for all data acquisition and prediction model development. HPLC was the reference method used to measure the concentration of glucose, fructose, sucrose, maltose, and turanose in honey. Color was measured using a Pfund colorimeter and the Pfund scale, which ranges from 0 to 140 mm (from very light-colored honey up to the darkest honey).

RESULT

The obtained NIR spectra of honey samples (Figure 2) were used to create prediction models for quantification of glucose, fructose, sucrose, maltose, and turanose content, as well as color. The quality of the prediction models was evaluated using correlation diagrams (Figures 3–8) which display a very high correlation between the NIR prediction and the reference values. The respective figures of merit (FOM) display the expected precision of a prediction during routine analysis

CONCLUSION

This Application Note displays the benefits of using near-infrared spectroscopy for quality control of honey. Color, along with glucose, fructose, sucrose, maltose, and turanose content can be measured simultaneously in only a few seconds. Measurements performed with NIR spectroscopy do not need any sample preparation nor solvents, saving users time and money. By using NIRS, only one analytical technology is required for sample measurement, compared to other conventional methods (Table 1). Finally, NIRS does not require skilled technical operators to perform the measurements, unlike HPLC.

3. Waters Corporation: High-Throughput Measurement of Compound Solubility and Physical Form with BMI

- Application note

- Full PDF for download

Aqueous solubility of small molecule compounds is an essential parameter during the hit-to-lead stage of drug discovery as well as during lead optimization and formulation. Low solubility can impact biological assays in a number of ways, including underestimated potency and toxicity, inaccurate structure-activity relationships (SAR), and difficult to interpret results. Poor bioavailability and underestimated toxicity directly impact downstream formulation and manufacturability of dosage forms – increasing development costs and reducing the chances of a drug candidate’s success.1–3

In this application note, we introduce backgrounded membrane imaging (BMI) on the HORIZON® system as a rapid and sensitive high-throughput method for compound solubility measurement. Particle analysis with BMI is easy to perform, requires as little as 25 of sample, and is unaffected by solvents or other media components. In addition, highly resolved images and shape distribution data provide valuable information on morphology of precipitated solids for more comprehensive solubility characterization.

Results and Discussion

BMI Overcomes Limitations of Other Solubility Screening Methods

Despite its critical importance at early stages, current methods for solubility measurement have limitations that affect reliability and/or time to results (Figure 1). In the more cumbersome multi-step methods, precipitates are removed by filtration or centrifugation, and concentration of compound remaining in solution is measured by various detection technologies such as UV absorbance or mass spectrometry coupled with HPLC. These methods are not only time consuming and inefficient, but can be affected by compound sticking to filters, incomplete removal of low-density aggregates by centrifugation, and interference by solvents and matrix impurities.

How BMI Works

The HORIZON® system system uses sophisticated image-processing techniques coupled with a simple workflow to acquire and analyze particle data. First, the HORIZON® membrane plate wells are measured to generate a background image (Figure 2a). Samples are then pipetted directly onto the membrane wells and filtered through by vacuum, capturing insoluble particles on the surface. The same wells are re-imaged in the HORIZON® instrument. After measuring, the software aligns and processes background and sample images pixel by pixel so that background texture is eliminated, and particles can be viewed in high contrast with minimal interference from membrane surface imperfections (Figure 2b).

Conclusion

Here, we have demonstrated how high-throughput membrane imaging with BMI on the HORIZON® system offers reliable, informed solubility assessment of small molecule compounds. In addition, imaging provides valuable information on solid state morphology for better interpretation of solubility results. Whether used as a primary solubility screening method, an orthogonal technique, or as a check to eliminate problematic candidates prior to in-depth characterization, implementing BMI technology can accelerate drug discovery and early ADME workflows - providing more complete information with less time and less material than traditional methods.