News from LabRulezICPMS Library - Week 38, 2025

LabRulez: News from LabRulezICPMS Library - Week 38, 2025

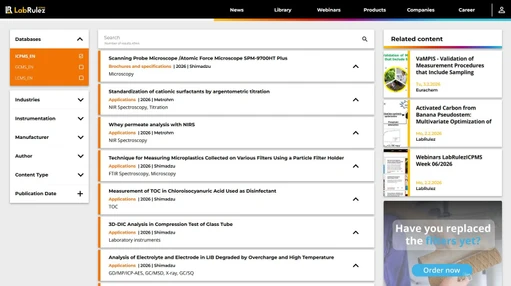

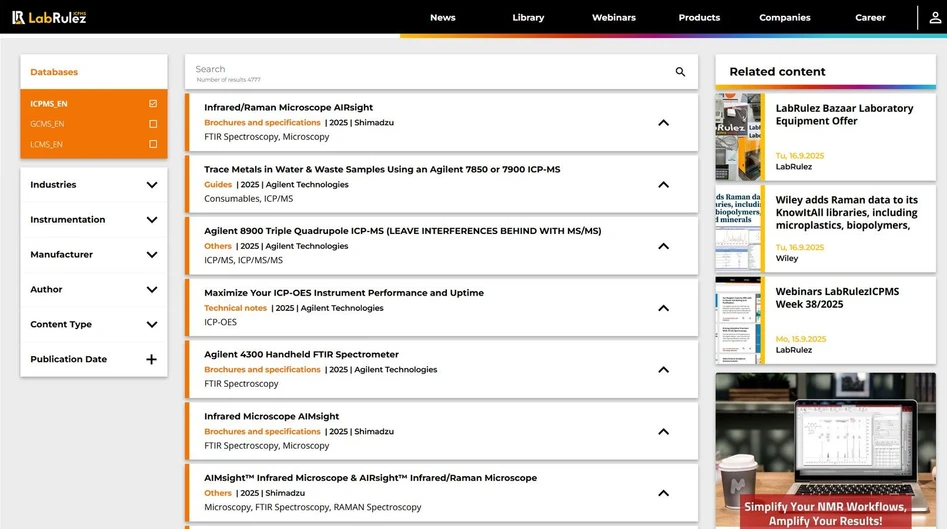

Our Library never stops expanding. What are the most recent contributions to LabRulezICPMS Library in the week of 15th September 2025? Check out new documents from the field of spectroscopy/spectrometry and related techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT SPECTROSCOPY/SPECTROMETRY RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezGCMS libraries.

This week we bring you application note by Shimadzu and poster by Thermo Fisher Scientific!

1. Shimadzu: Analyzing Microscopic Contaminants Embedded in Recycled Plastic

- Application note

- Full PDF for download

Reusing plastic waste is key to achieving a carbon-neutral society, which is why targets have been established for levels of recycled plastic in plastic products. But quality control of recycled plasticsis essential for maintaining the functional properties of plastic productssince impropersorting, transporting, and processing can all lead to contamination of recycled plastic. Determining the type and quantity of contaminants in recycled plastic is important since they can have a significant negative impact on product performance in certain applications.

Shimadzu’s infrared microscopes use high-speed mapping analysis to quickly find and characterize contaminants dispersed in recycled plastic, and Shimadzu’s particulate analysis program also provides a convenient and simple tool for determining the morphology and numbers of contaminants.

This Application News describes using this equipment and tools to analyze contaminants in recycled plastic material that was formed into a film.

High-Speed Mapping Analysis of Recycled Plastic

For recycled plastic with a relatively simple infrared spectrum, contaminants embedded in the plastic can be analyzed without removing them from the plastic. This is achieved by configuring wavenumber ranges (exclusion ranges) that exclude the peaks of the recycled plastic in the settings of the high-speed mapping software. In this example, a thermal press was used to form recycled plastic composed of PE and PP into a plastic film approximately 100 µm thick. The high-speed mapping settings were then configured to detect peaks in wavenumber regions that contain hydroxyl groups and carbonyl groups that are not normally found in PE or PP. Table 1 shows the analysis conditions in detail. Background readings were obtained from an area of the film with no contaminants.

- Equipment: IRTracer-100, AIMsight

- Software: AMsolution, high-speed mapping software, particle analysis program

Conclusion

This Application News describes a simple and rapid method for analyzing and characterizing contaminants in recycled plastic using high-speed mapping analysis with an infrared microscope and data analysis with a particle analysis program. Areas of recycled plastic with no contaminants were scanned once, whereas areas with contaminants were scanned multiple times (50). This allowed a wide area of recycled plastic to be analyzed quickly with minimal noise in the recorded infrared spectra, reducing the analysis time to around just one-fifteenth of the time needed if every part of the recycled plastic was scanned 50 times. Also, using a thermal press to form recycled plastic pellets into a film enabled the efficient characterization of large numbers of contaminants by transmission spectroscopy and the ability to calculate their numbers in the pellets.

2. Thermo Fisher Scientific: Highly sensitive analysis of distillate products per ASTM Method D8110 using single quadrupole ICP-MS

- Poster

- Full PDF for download

Control of impurities in the petrochemical industry is an essential step to ensure the quality of the crude, intermediates, and finished products. In many laboratories, the analysis of crude, intermediates, and finished products, including light and middle distillates for trace elements, is accomplished using inductively coupled plasma optical emission spectrometry (ICP-OES) or inductively coupled plasma mass spectrometry (ICP-MS). However, the regulations and specifications for content of elemental impurities are becoming more stringent, which enforces determination of these impurities at lower concentration levels. Due to its higher sensitivity and specificity, ICP-MS is becoming the technology of choice for laboratories. The American Society for Testing and Materials (ASTM) issues standard D8110 that outlines the specifications and test method for elemental analysis of distillate products by ICP-MS. Analysis of combustible organic samples like naphtha, vacuum gas oil (VGO), or aviation turbine fuel (ATF) using ICP-MS could be challenging compared to conventional aqueous samples mainly because unexpected and intermittent extinguishing of plasma as well as carbon deposition in the interface region extracting ions into the mass spectrometer. The direct introduction of volatile organics increases the plasma load due to their high vapor pressure, causes destabilization of plasma and results in poor sensitivity and precision of measurements. Carbon-based interference on key analytes, such as chromium or vanadium, cause additional concerns but can typically be overcome using kinetic energy discrimination (KED) on single quadrupole instruments, or other typical gases used in collision/reaction cells1 . This poster discusses a complete workflow developed using the Thermo Scientific iCAP MSX ICP-MS (Figure 1) for the sensitive determination of elemental impurities in typical distillate samples including light naphtha, heavy naphtha, and crude oil samples.

Materials and methods

An analytical method was developed with single quadrupole ICP-MS (iCAP MSX ICP-MS) for elemental analysis of a range of typical petroleum samples with varying physical and chemical properties.

Data Analysis

The data acquisition and processing were done using Thermo Scientific Qtegra Intelligent Scientific Data Solution (ISDS) Software.

Conclusions

The results obtained from the experiments described in this application note demonstrate the following:

- The proposed method and instrument set-up for elemental analysis of different petroleum products using the iCAP MSX ICP-MS represents a viable solution for laboratories performing oil and refinery product testing.

- The combination of the sample introduction system together with a uniquely robust plasma generation system and a powerful CRC allows for sensitive analysis and comprehensive interference removal for all elements commonly analyzed in the industry.

- The use of KED with helium provided effective for removal of polyatomic interferences commonly observed in such challenging matrices, as was demonstrated by the detection limits and blank equivalent concentrations (BECs) achieved.

- The method therefore allows the accurate and precise determination of a total of 28 elements in different kinds of distillate products, as was demonstrated by the results obtained in the spike recovery test.

- If needed, other reactive gases can be used in a multi-mode analysis performed during a single aspiration of a sample, including alternative cell gases such as hydrogen. Thanks to the fast gas switching in the QCell CRC, the added time for switching cell gases is often negligible for the overall analysis time per sample.

- The novel design of the sample introduction system of the iCAP MSX ICP-MS allows to easily switch between oxygen addition and the use of argon gas dilution without the need to change gas connections.