News from LabRulezICPMS Library - Week 34, 2025

LabRulez: News from LabRulezICPMS Library - Week 34, 2025

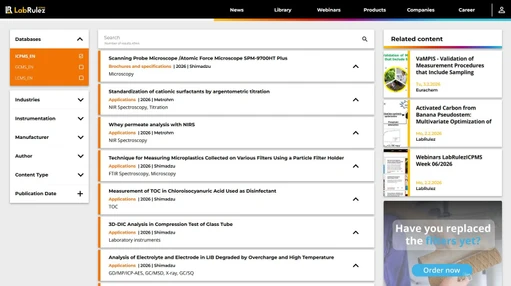

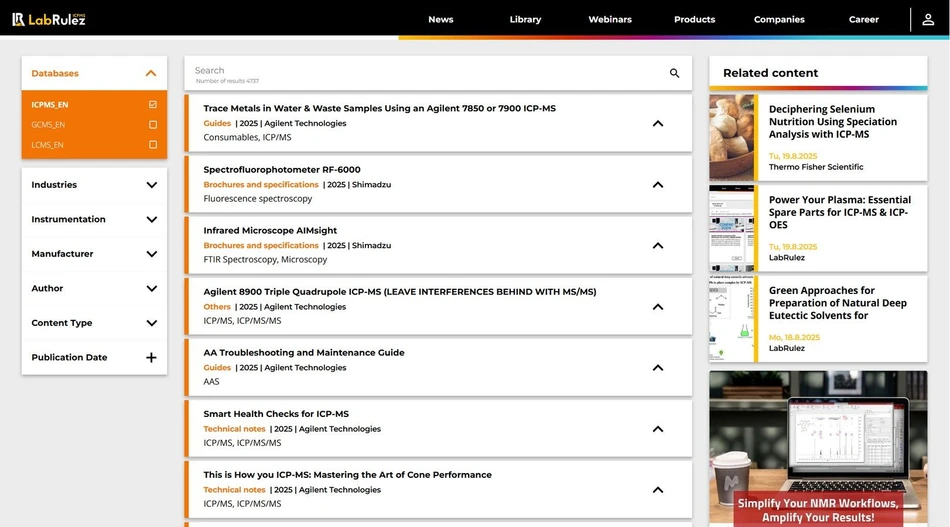

Our Library never stops expanding. What are the most recent contributions to LabRulezICPMS Library in the week of 18th August 2025? Check out new documents from the field of spectroscopy/spectrometry and related techniques!

👉 SEARCH THE LARGEST REPOSITORY OF DOCUMENTS ABOUT SPECTROSCOPY/SPECTROMETRY RELATED TECHNIQUES

👉 Need info about different analytical techniques? Peek into LabRulezLCMS or LabRulezGCMS libraries.

This week we bring you application notes by Agilent Technologies, Metrohm and Shimadzu and poster by Thermo Fisher Scientific!

1. Agilent Technologies: Elemental Analysis of Solid Electrolyte Lithium Lanthanum Zirconate Tantalum Oxide by ICP-OES

Quantification of Li, La, Zr, and Ta in electrolyte for all-solid-state Li-ion batteries by Agilent 5800 ICP-OES

The ceramic material Lithium Lanthanum Zirconate Tantalum Oxide (LLZTO) is being investigated as a solid electrolyte in LIBs.1 Properties such as high-ionic conductivity, as well as excellent chemical and thermal stability, make LLZTO a promising candidate for enhancing the performance and safety of solid-state LIBs. Research and development (R&D) scientists are actively exploring dopant strategies to further enhance its formulation. However, challenges such as impurities, inclusions, and inhomogeneities in electrolytes still pose significant risks, potentially degrading performance or inducing failure mechanisms. To verify that the sample composition aligns to theoretical formulas, the matrix elements of LLZTO must be determined using a robust, reproducible, and accurate analytical technique such as inductively coupled plasma-optical emission spectroscopy (ICP-OES). The technique is especially useful for the simultaneous measurement of multiple elements in samples, due to its speed, stability, and tolerance to high total dissolved solids (TDS). Battery scientists also require methods to analyze the elemental composition of spent electrolytes to investigate changes that occur during charge and discharge cycles. These analyses support the production of consistent and reliable materials, helping to develop ASSBs.

Both the Agilent 5800 Vertical Dual View (VDV) and 5900 Synchronous Vertical Dual View (SVDV) ICP-OES instruments have been widely adopted across the LIB value chain to address the varied analytical needs of the industry.2 The instruments are ideal for labs dealing with novel materials, samples with high lithium matrices, and multi-element analyses where speed, stability, and data accuracy are critical. The capabilities of Agilent ICP-OES instruments are beneficial in overcoming several challenges faced by battery researchers and manufacturers, as follows:

- High lithium matrix: Li-rich matrices typically contain high levels of TDS. Instruments such as the 5800 and 5900 that are capable of analyzing such concentrated Li samples over extended periods—without requiring frequent shutdowns and maintenance—offer a significant operational advantage.3,4

- Unknown sample constituents: Uncharacterized elements in the sample can lead to batch-to-batch variations. However, the screening capabilities of the 5800 or 5900 using IntelliQuant Screening allow visual review of sample composition without the need for exhaustive multi-element calibrations. IntelliQuant Screening enables quick screening and comparative analysis of samples, saving both time and resources.5,6

- Instrumental drift: Measurement drift over time introduces uncertainty and undermines confidence in temporal data comparisons. The 5800 and 5900 instruments which are engineered without moving optical components— eliminating alignment drift—provide superior long-term stability and reduce maintenance-related interruptions.7

In this study, the 5800 VDV ICP-OES was used to measure the four major elements, lithium (Li), lanthanum (La), zirconium (Zr), and tantalum (Ta), in a research sample of a Ta-doped LLZTO powder to verify its molar percentage composition.

Elemental characterization is critical throughout the entire development pipeline, from early R&D to pilot and full-scale manufacturing. Screening precursor materials before their incorporation into solid electrolyte formulations is a key part of process quality control at all production scales, helping to minimize troubleshooting, reduce failure rates, and lower cell-to-cell variability.

Analysts typically evaluate ICP-OES methods using a number of performance criteria to ensure reliability and suitability for their specific application. These include parameters such as linearity of the calibration, detection limits, accuracy, precision, robustness, and matrix tolerance. In this study, precision, short-term stability, molar percentage composition of major elements, and the long-term stability of the method were evaluated.

Experimental

Instrumentation

The elemental analysis of the LLZTO electrolyte samples was performed using an Agilent 5800 VDV ICP-OES, equipped with the following hardware components:

- Proprietary Cool Cone Interface (CCI) technology: designed to minimize interferences, such as recombination and absorption caused by the cooler plasma tail.

- A high-precision thermostatted polychromator with no moving optical components: designed to provide excellent long-term stability and exceptional resolution.

- Vista Chip III detector: capable of processing speeds up to 1 MHz, allowing for simultaneous measurements of all wavelengths in less than half a second.

The 5800 was fitted with a SeaSpray nebulizer, a double-pass cyclonic spray chamber, and an Easy-fit one-piece torch with 1.8 mm id quartz injector torch. The instrument's SSRF system produced a robust plasma suitable for high-matrix samples, such as LLZTO electrolytes.

Agilent ICP Expert Pro software was used to control the 5800 ICP-OES, optimize and run the method, and to process the data. The software includes smart tools such as IntelliQuant Screening that help with the development of robust and reliable methods for analyzing precursor chemicals such as LLZTO. The software also includes easy-to-use automated algorithms for ICP-OES background correction including Fitted Background Correction (FBC). Background correction is commonly used in ICP-OES applications to minimize spectral interferences from other elements in the sample, which could otherwise skew analyte measurements. Analysts can also use the custom columns option within ICP Expert to report the quantitative results for Li, La, Zr, and Ta as molar percentages. The software applies formulas and conversions, providing additional reporting options for materials characterization.

Conclusion

The Agilent 5800 VDV ICP-OES in radial view mode was used for the quantitative analysis of Li, La, Zr, and Ta in an LLZTO sample, an all-solid-state precursor electrolyte material used in next generation lithium-ion batteries. Excellent calibration linearity (R> 0.9999) and method detection limits ranging between 13.12 and 48.54 mg/kg were achieved for the four elements. The Agilent ICP Expert software was used to convert the quantitative results for Li, La, Zr, and Ta from mg/kg to molar percentages, facilitating direct comparison to theoretical stoichiometry.

The 5800 ICP-OES method successfully addressed several analytical challenges presented by the application, making it suitable for both R&D and future-proofing applications in mainstream production, including the production of materials from spent batteries.

- Complex sample matrices: The 5800 instrument’s robust vertical plasma, SSRF generator, and Cooled Cone Interface effectively handled the high concentration of Li, La, Zr, and Ta in the sample matrix, overcoming concerns regarding high-levels of TDS.

- Identifying unknown sample constituents: IntelliQuant Screening provided a comprehensive view of both quantified and non-quantified elements in the samples, complementing the quantitative analysis in establishing the stoichiometric composition of LLZTO. IntelliQuant Screening also facilitated rapid comparative assessment of the elemental profiles of samples based on relative abundances, with user-friendly data visualization options such as pie charts.

- Instrumental stability: The 5800 instrument's exceptional stability—enabled by a design that eliminates moving optical components and diffraction gratings—was demonstrated by excellent recoveries of Li, La, Zr, and Ta over four hours during 145 measurements of LLZTO samples.

The 5800 VDV ICP-OES method supports fundamental research and QA/QC by ensuring the consistent and accurate composition of synthesized electrolytes. The consistency of LIB-electrolyte materials is important to meet desired performance targets, enhance safety, and extend the longevity of solid-state batteries.

2. Metrohm: Phosphates speciation with Raman spectroscopy

A simpler alternative to wet chemical analysis methods

- Application note

- Full PDF for download

Phosphates are integral to a wide range of industrial processes, from agriculture and food production to water treatment and pharmaceuticals. The ability to accurately identify and monitor the transformation of different phosphate species—such as phosphoric acid (H3PO4), dihydrogen phosphate (H2PO4−), hydrogen phosphate (HPO42−), and phosphate (PO43−)—is essential for optimizing these processes and ensuring compliance with regulatory standards. Each phosphate ion species exhibits unique chemical properties and behaviors, influencing their reactivity, solubility, response to excitation, and roles in industrial applications. This Application Note demonstrates the ability of Metrohm’s MIRA XTR handheld Raman instrument to speciate phosphate ions.

CONCLUSION

Raman spectroscopy provides real-time analysis of the analyte species present in solution, permitting precise identification of phosphate ions as they transition with pH changes. A small handheld Raman system like MIRA XTR achieves fast and direct confirmation of wet chemical techniques like titration with no need for reagents or complex sample preparation. Additionally, it enables continuous monitoring of dynamic systems, providing detailed and accurate insight into the speciation process and reducing the potential for error in measurements.

3. Shimadzu: Evaluation of Dynamic Deformation Behavior of LPSO Type Magnesium Alloy by AE Method and High Speed Camera

- Application note

- Full PDF for download

The Long-Period Stacking Ordered (LPSO) type magnesium alloy, which was developed by Kawamura et al. 1) in 2001, simultaneously achieves high strength, high heat resistance, and incombustibility, and has been an object of active research. Kawamura et al. realized the LPSO structure with Mg97Zn1Y2 by the rapid solidification powder metallurgy method. The LPSO structure, as its name suggests, is a structure with a long-span atomic arrangement in comparison with conventional magnesium alloys.

It has been reported that a deformation mechanism called kink deformation occurs in microregions in this LPSO structure, and the formation of kink deformation bands is thought to contribute to high strength. Hagihara et al. 2) performed compressions tests of unidirectionally solidified materials having a LPSO single phase structure and investigated the orientation change caused by the deformation bands. The orientation change caused by deformation bands does not take a fixed value like that in the case of twinning deformation, but rather, displays a wide distribution. Based on this, some researchers have maintained that deformation bands are caused by kink deformation and not twinning deformation.

On the other hand, Kishida et al. 3) proposed that the distinctive deformation bands formed by Mg-Al-Gd system alloys that contain the LPSO phase are not formed by kink deformation, but by twinning deformation followed by crystal rotation. Since the twins that occur here are a twin system called {112ത1} tensile twins and have rarely been reported in magnesium and its alloys, it is possible that the LPSO structure plays a critical role in the formation of this twin system. Thus, there are still many unknown points in connection with the kink deformation of the LPSO phase, and it is necessary to elucidate the detailed behavior of this kink deformation for further alloy development of LPSO type magnesium alloys.

In previous work, we evaluated the dynamic deformation and fracture mechanism of various magnesium alloys by the acoustic emission (AE) method 4)-11). This article introduces an example of observation of kink deformation bands in a LPSO type magnesium alloy by a combination of the AE method and a high speed camera.

Conclusion

This article introduced an example of observation of kink deformation bands with a high speed camera. In research and development of structural materials, observation and analysis of dynamic deformation behavior are necessary and indispensable. The AE method is almost the only method that can capture the internal dynamic behavior of materials in real time. However, because AE is an indirect evaluation method and the main observation region is the ultrasonic region from 100 kHz to 2 MHz, direct observation of the actual phenomena at the AE generation source was difficult with conventional techniques, even when using a high speed camera. As a result of improvement in the performance of high speed cameras in recent years, a framerate of 10,000,000 FPS and high photosensitivity can now be achieved simultaneously, enabling observation of the actual phenomena at substantially the same sampling rate as that in AE measurement.

As introduced in this article, it is expected to be possible to capture phenomena that could not be observed until now by using a combination of direct observation of the material surface by a high speed camera and in-situ observation of dynamic behavior, including the interior of the material, by AE analysis. Since this is considered to be an extremely powerful technique, not only for observation of kink deformation bands, but also for elucidation of a variety of other dynamic behaviors, including phase transformation and fracture phenomena such as crack initiation and growth, further expansion of applications as a research technique is expected.

4. Thermo Fisher Scientific: Inductively Coupled Plasma Mass Spectrometry for the Analysis of Metal Content in Single Chinese Hamster Ovary Cells

- Poster

- Full PDF for download

Elements, particularly metals, can heavily influence protein production for therapeutic applications (e.g., growth, viability, yield, and protein quality). ICP-MS has been extensively used to determine elemental contents in cell culture media, both in fresh and spent media. However, exploring intracellular elemental content to establish potential links between growth media and cell culture performance was previously impossible.

ICP-MS can be operated in multiple modes: conventional mode (optimal for fresh/spent media) or the novel single-cell mode (capable of intracellular investigation). In single-cell mode, the elemental content of individual cells (as opposed to bulk-cell analyses) can be determined, and information about the distribution of elements within a cell population could also be obtained. Multiple studies have shown the successful use of single-cell ICP-MS for cell types such as yeast, alga, and red blood cells [1]. However, its application for CHO cells, commonly used to produce therapeutic proteins, has not been explored. This study aims to develop a single-cell analysis method, from CHO cell preparation to data acquisition and processing, to determine metal content in individual cells. Such information may provide insights to appropriately tailor cell culture media for better control of cellular metal uptake.

MATERIALS AND METHODS

Single-cell ICP-MS System Setup

A single-cell sample introduction system (Glass Expansion, Melbourne, Australia) was connected to a Thermo Scientific™ iCAP™ TQ ICP-MS (Bremen, Germany) for single-cell analyses. Dilute cell suspensions were delivered into the ICP-MS system through a syringe pump.

Data Acquisition and Analysis

Thermo Scientific™ Qtegra™ Intelligent Scientific Data Solution™ Software was used to acquire transient signal (5 ms dwell time, time resolved acquisition mode). Kinetic energy discrimination (KED) mode was used to quantify 57Fe, while triple quadrupole (TQ)-O2 mode was used to quantify 31P (as 31P16O) and 80Se (as 80Se16O). An in-house application was used for the automatic processing of the exported Qtegra data. Advanced functions, such as consecutive cell signal detection and correction, were also incorporated in this application.

CONCLUSIONS

- A protocol for the preparation of viable CHO cells for single-cell analysis was established.

- Single-cell capabilities for the iCAP TQ ICP-MS were demonstrated with commercially available reference materials.

- A method for estimating the average cellular elemental concentrations through bulk-cell analysis was developed.

- Single-cell ICP-MS provides more detailed information on the distribution of iron in individual CHO cells (fg/single cell) as compared to bulk-cell analysis (average fg/cell).