Thermal Analysis Kinetics for Predicting Chemical Reactions

Understanding How Different Conditions Influence Chemical Reaction Rates

Program

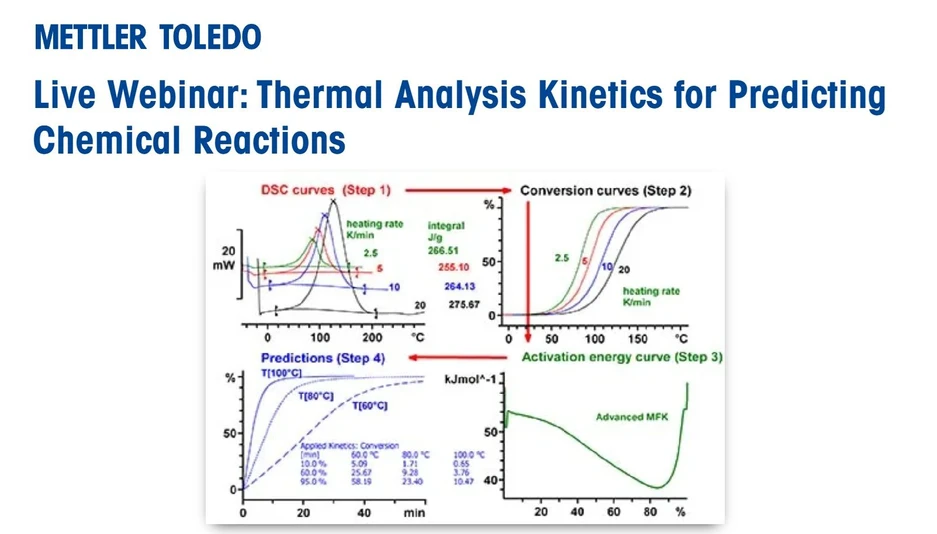

- What are thermal analysis kinetics and why do we use them?

- Basic principles and theory of reaction and model-free kinetics

- What type of predictions can be made?

- Useful DSC and TGA applications for predicting reaction behavior

Interactive Q&A

Reaction kinetics is a useful method for studying the rate at which a chemical reaction proceeds, enabling predictions to be made about how a material will behave outside the practical measurement range. Kinetics provides information such as aging, oxidation stability, and shelf life, without the need to observe materials over long periods of time. These predictions are of fundamental importance for process development and the optimization of chemical processes.

How Are Reaction Kinetics Measured?

The kinetics of thermal processes are typically measured by differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), providing information about the influence of temperature, time, concentration, catalysts, and inhibitors. Computational tools have been developed, which allow us to keep the number of practical experiments to a minimum and provide valuable information about safety, scale-up, and stability.

What Can Be Measured?

- Predicting reaction behavior: The most important application of kinetics methods in thermal analysis is to predict chemical reaction behavior under conditions where measurements are difficult to perform or where the reaction times are very short or very long.

- Conversion rates: Kinetics methods are also useful for calculating the conversion rate of a starting material to the final product. This so-called global reaction describes how fast the overall chemical reaction occurs.

Join the webinar and learn about different kinetic methods and why they are so useful. Discover real-world examples of how kinetics is used in industries such as food, pharma, and chemicals to study shelf-life, process safety, curing, decomposition, and denaturation.

We conclude with a live Q&A session so don’t forget to prepare your questions!

- 31. 7. 2025 8:00, English

- 31. 7. 2025 16:00, English

Presenter: Angela Hammer (Dr. sc. nat. ETH)Dr. Angela Hammer received a Ph.D. in Analytical Chemistry (development of immobilized components for the use in ion-selective electrodes based on polyurethane membranes) from the Institute of Organic Chemistry at the Swiss Federal Institute of Technology in Zürich, Switzerland. She then joined Sika Technology AG in Zurich, Switzerland, as an analytical chemist. In 2007, she joined METTLER TOLEDO and has worked there since as an application specialist for Thermal Analysis. In her present position, she uses, teaches, and supports DSC, TGA, TMA, and DMA instruments for the METTLER TOLEDO’s Materials Characterization Group located at the head office in Switzerland.